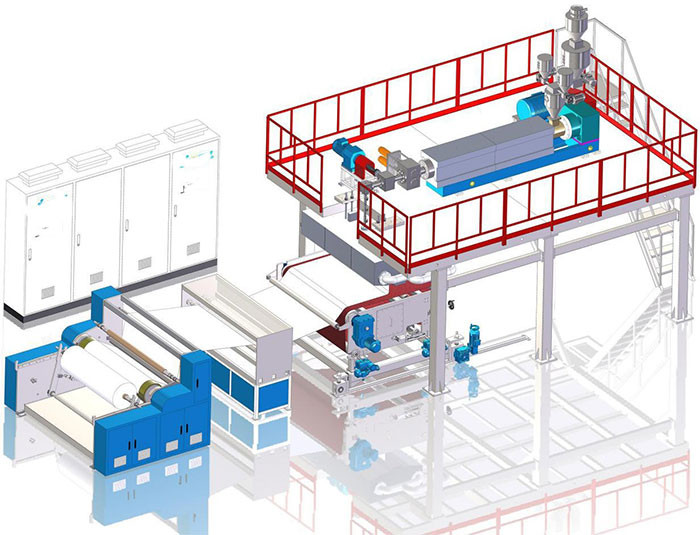

Línea de producción de tejido soplado en fusión de PP OMEGA-M600

Ⅰ. Parámetros técnicos principales de fOMEGA-M600 Línea de producción de tejido soplado en fusión PP

1. Usage condition

1)Location: indoor safety area

2)Power supply: 50Hz, 3-phase415V, neutral, grounding

3)Temperature: 0~40 ℃

4)Cooling water source:Centralized water supply filter, water temperature below 30 ℃,water pressure 0.4-0.6MPa

5)Gas source pressure: 0.4~0.8MPa

2. Applicable raw material:MFI1500or overspecial material for melt blown cloth is required

3. Production line speed(Max.):8.5m/min

4. Total installed power: 120kw

5. Center height of extruder: 1000mm ± 50mm

6. General layout size of production line:See water and electrical layout for details, provided after a contract is established

7. Operation direction: left mobile phone (when facing the operation panel, the left mobile phone is used to load materials from the right and the left to exit the pipe, otherwise, the right mobile phone)

8. Fiberdiameter:2~5μm

9. Finished fabric: Width: 600~700mm with weight range of20-100g/m2

10. Production capacity: 50kg/hr

II.Configuración de la línea de producción de tejido soplado en fusión de PP OMEGA-M600

|

Name |

Number |

|

1. Feeding device |

1Set |

|

2. Screw extruder |

1Unit |

|

3. Screen changer |

1Set |

|

4. Gear pump |

1Unit |

|

5. Melt pipe |

1Set |

|

6. Combined spinneret die head |

1Set |

|

7. Hot-air system |

1Set |

|

8. Air heater |

1Unit |

|

9. Suction fan |

1Unit |

|

10. Connecting duct |

1Set |

|

11. Receive net |

1Set |

|

12. Automatic slitting and rewinding machine |

1Unit |

|

13. Electric control system |

1Set |

|

14. Electret processing equipment |

1 Unit |

Ⅲ. Equipos de la línea de producción de tejido soplado en fusión de PP OMEGA-M600 en detalle

|

1. Feeding device |

|

|

Feeding capacity |

100Kg/h |

|

Motor power |

2.2KW |

|

2. Screw extruder |

|

|

Screw and barrel |

|

|

Material |

38CrMoAlA |

|

Nitrided layer thickness |

0.5-0.7mm |

|

Surface of screw hardness |

HV>=740 |

|

Surface ofbarrel hardness |

HV>=940 |

|

ExtruderL/D |

33:1 |

|

Screw diameter |

65mm |

|

Heating zoneson barrel |

5 Zones |

|

Total heating power |

About21KW |

|

Heating method |

Cast aluminum heater |

|

Drive motor |

Zhejiang Yongfa brand |

|

Speed governor |

ABB governor in frequency conversion way |

|

Drive Power |

22KW |

|

3. Gearbox |

|

|

Material of the house |

QT200 |

|

Gear type |

Helical gears |

|

Material of the gear |

20CrMnTi |

|

Heat treatment of the gear surface |

Quenching |

|

Bearings |

Chinese famous bearing |

|

|

Lubricating system |

Press system |

|

|

Cooling System |

Internal cooling and forced circulation cooling |

|

|

Outside barrels with a heat preservation cover |

||

|

4. Screen changer |

||

|

Structure characteristic |

Column type screen changer with double working place |

|

|

Screen changing drive |

Hydraulic system, non-stopandauto-changer |

|

|

Pressure sensor |

Chinese famous brand of Chengdu Xianda |

|

|

5. Melt pump |

||

|

Origin |

China |

|

|

Specification |

50CC |

|

|

AC inverter control |

Denmark Danfoss inverter controller |

|

|

Drive |

USA FALK inverter motor |

|

|

|

Motor power |

2.2 KW |

|

Pressure sensor |

Before melt pump:Italian Gefran brand Before screen changer & after melt pump:SAND brand |

|

|

6. Melt pipe |

||

|

Material |

Seamless stainless steel pipe |

|

|

Heating type |

Electric heater |

|

|

Insulation type |

Rock wool+stainless steel external insulation |

|

|

7. Combined spinneret die head |

||

|

Material |

1Cr17Ni2 |

|

|

Die head length |

900mm |

|

|

Holes length |

800mm |

|

|

Nozzle hole diameter |

0.3mm |

|

|

Spinneret hole length to diameter ratio |

10:1 |

|

|

Heat ing power |

10KW |

|

|

The spinneret converts the melt into a thin stream, which is drawn by a high temperature jet stream to form a microfiber. |

||

|

8. Hot-air system |

||

|

Enter port flow |

11m3/min |

|

|

Power |

30KW |

|

|

9. Air heater |

||

|

Heating power |

100KW |

|

|

Material of tank and tube |

Stainless steel |

|

|

Keep warm type |

Stainless steel be usedoutside theinsulating layer use |

|

|

Roots blower |

Provide high pressure air to make the draft air speed to the scope of the technical requirements by frequency converter, roots blower can easily change the output of the air flow. |

|

Roots blower air heating pot |

Heat the air from the Roots blower,in order to achieve the temperature of the process requirement. |

|

10. Suction fan |

|

|

Suction air volume |

25380m3/min |

|

Power |

30KW |

|

11. Connecting duct |

|

|

Material |

Stainless steel |

|

12. Receiving netting machine |

|

|

Line speed |

0-50m/min |

|

Net curtain material |

PET |

|

Receiving net |

Overlapping structure |

|

Spinneret distance adjustment |

±150mm |

|

Installing form |

level shift |

|

Driving power |

3.7KW |

|

|

|

13. Automatic slitting and rewinding machine |

|

|

|

Line speed |

0-50m/min |

|

|

|

Edge trimming unit |

5Sets of circular knife, the position can be adjusted. |

|

|

|

Driver |

Variable frequency motor |

|

|

|

Power |

1.5KW |

|

|

|

Gas expansion axis |

Core shaft 3 inch |

|

|

|

14. Electric control system |

||

|

|

Inverter |

ABBbrand or equivalent |

|

|

|

contactor |

SCHNEIDERbrand or equivalent |

|

|

|

Relay |

IDECof Japanbrand or equivalent |

|

|

|

Low voltage breaker |

SCHNEIDERbrand or equivalent |

|

|

|

Air switch |

SCHNEIDERbrand or equivalent |

|

|

|

|

Button & indicator light |

SCHNEIDERbrand or equivalent |

|

|

Indicator gauge |

AUTONICSof Koreabrand or equivalent |

|

|

15. Electret treatement equipment |

|||

|

Input voltage |

220V/50HZ |

||

|

Maximum output voltage |

40KV |

||

|

Hand width |

600mm |

||

|

16. Die head cleaning device |

|||

|

Calcinator size |

Φ400×1200 |

||

|

Heating power |

11KW |

||

- Información

- Su solución de vida útil de la extrusora

- Producto de membrana de ultrafiltración de cerámica y su proceso de producción

- Material de fabricación de barriles y tornillos para extrusoras de alimentos y productos farmacéuticos

- ¿Desgaste por fricción extrema? ¿Corrosión extrema?

- Línea de producción de tejido soplado en fusión de PP OMEGA-M600

- Máscara de equipo de tela soplada en fusión | Proporcione rápidamente equipos de producción de mascarillas

- Universal Application Reason of Bimetallic C-type Liner

- Aleación de alta resistencia base hierro Ω101

- Aleación inoxidable de alta resistencia base níquel Ω301

- Aleación de alta resistencia de hierro-cromo fundido para casquillo Ω101A

- Contáctenos

-

Shanghai Omega Machinery Co., Ltd.

Dirección: No.168 Hualian Road, Putuo District, Shanghai City

Contacto: Williams Wu

Tel.: +86-021-69921527

Celular: +86-18616920618

Fax: +86-021-69921567

E-mail: alphawu@126.com

WeChat No.: wxsyyk1203will

-