Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

How does single extruder cylinder work?

Sep 09,2016

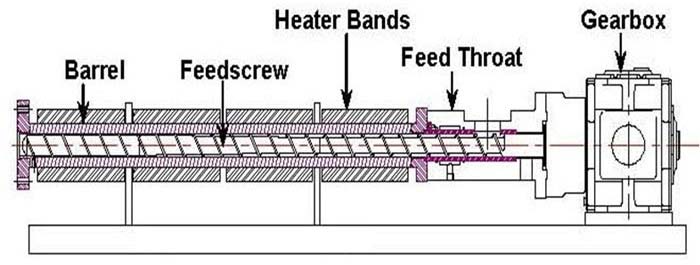

Add proper water or liquid into raw materials and continue stirring. Extrude the mixed materials by high pressure extrusion head or metal mesh. In general, the material should be put into a cylindrical vessel and extrude it by screw.

Single extruder cylinder consist of three parts according to the screw diameter, pitch, screw depth. The last thread of spout is called transportation section. Materials can not be plasticized here, but need to warm up and extrude for preparation. The material used to be considered loose body, but it is proved solid body later. The second parts is called compression section. The temperature here should achieve the degree for plasticizing. The compression ratio is 3: 1 and the material will be transported to the third part after completing the process of plasticizing. The third part is the metering section. The plasticizing temperature should be maintained here. It is like metering pump and supply materials to the nose. The temperature can not be lower than the plasticizing temperature, generally slightly higher.

- Information

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- What countermeasures can be taken to improve the dimensional and positional accuracy of profiles during the profile production process?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-