Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Iron-base Ω101 Alloy and Its Characteristics

Alloy Ω101 is a special type of metal with a lower melting point yet it offers high hardness and wear resistance. These features make the material suitable for use as an alloy layer on the surface of a barrel bore, extending the service life of the extruder or injection molding machine in which it is installed. After the standardized centrifugal casting method, we can create iron-base high borides Ω101 alloy with more types of carbides. Its main component is martensite white iron with a hardness rating of HRC 58~64, which is the same as X-102 alloy from Xaloy company in the USA.

The chemical components of the standardized iron-base abrasion-resistant Ω101 is shown below| C | Mn | Si | B | Cr | Ni | Fe |

| 3.0~3.8 | 0.5~1.3 | 0.5~1.3 | 1.5~2.3 | 1.5~2.5 | 4.5~5.5 | Balance |

Physical properties of the standardized iron-base abrasion-resistant Ω101 after standard centrifugal casting process

| Specific Gravity (Mean) | Density (Pound / Cubic foot) | Tensile strength (бb) | Breaking Strain (εfB) | Melting Point Range | Thermal Expansion Coefficient | Thermal Conductivity (BTU/H/ (Inch0F) | Modulus of elasticity ( kgf / mm ) |

| 7.40~ 7.70 | 0.274~ 0.30 | ≥50000 Pound / Inch2 | 0.30% | 2020 oF~ 2060 oF | 5.57x10-6 / oF | 17.5 | 18600 |

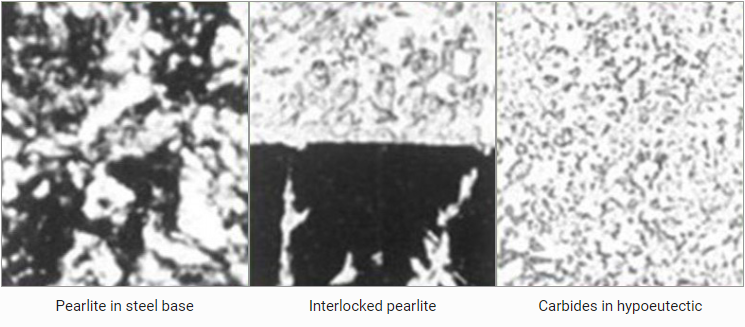

After centrifugal casting, alloy Ω101 forms the hypoeutectic structure as below:

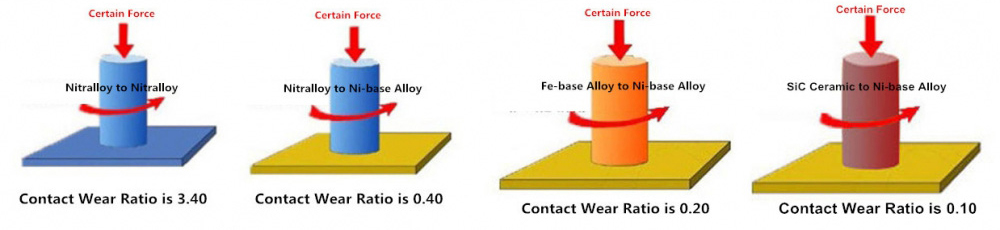

As image 4 shows, regarding the extruders or injection molding machines, the barrel and screw will mainly suffer two kinds of wear, one is called contact wear, and another is shear wear. Because the screw is installed in the barrel’s inner bore with a cantilever structure, the screw surface will grind the barrel inner bore’s wall harshly. The faster the screw is rolling, the heavier the abrasion. If we use the same material for making barrels and screws, the contact wear will be even worse. Numerous experimental and practical experience in the last thirty years prove that compared with other alloys, the martensite white iron shows the least contact wear, especially for the nitrided screw or the high speed steel screw. All the circumstances are getting better since we introduced the Ω101 alloy in 2008.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-