Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

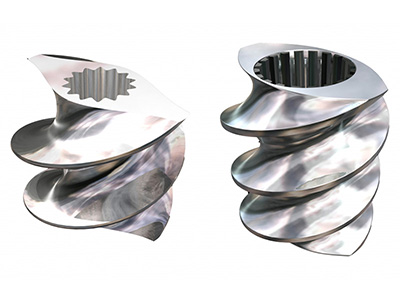

What are the screw elements of a twin screw extruder?

Jan 31,2024

Conveying Elements: These elements transport the material from the feed section to the discharge section of the extruder. They typically have a deep flight depth and low pitch to maximize material conveying.

Kneading Elements: Kneading elements are designed to mix and knead the material thoroughly. They usually have a shallower flight depth and higher pitch compared to conveying elements, allowing for better mixing and shear.

Mixing Elements: Mixing elements further homogenize the material by generating chaotic flow patterns and intense shear. They typically feature a combination of forward and reverse elements to enhance mixing efficiency.

Melt/Compression Elements: As the material progresses towards the end of the extruder barrel, melt or compression elements increase pressure and facilitate melting of the material. They often have a decreasing pitch and flight depth to compress and melt the material effectively.

Distributive Elements: Distributive elements help in distributing additives or fillers evenly throughout the material. They typically have a specialized geometry to ensure uniform dispersion without causing excessive shear.

Reverse Elements: Reverse elements create backflow within the extruder to enhance mixing and dispersion. They are designed with a reverse pitch to counter the forward flow of material.

Barrier Elements: Barrier elements are used to create a barrier between the material and the barrel wall, allowing for better control of residence time and melting characteristics.

Shear Elements: Shear elements induce additional shear forces to the material, aiding in its mixing and processing. They often have a sharp geometry to maximize shear effect.

These screw elements can be combined and arranged in various configurations to tailor the extrusion process to specific material properties and processing requirements.

Prev News Next News

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-