Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

What is the conveying element in a twin screw?

Feb 21,2024

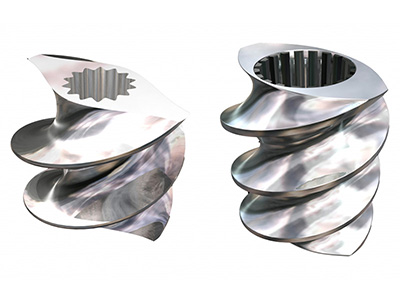

The conveying element serves as the linchpin of twin screw systems, facilitating the seamless transport of materials along the length of the screws. Through a carefully orchestrated interplay of helical flights and screw geometry, the conveying element ensures a consistent and controlled flow of substances, regardless of their viscosity or particle size.

Design Considerations

The efficacy of a twin screw system hinges on the meticulous design of its conveying elements. Engineers meticulously tailor the pitch, profile, and configuration of the conveying elements to suit the specific requirements of each application. Whether it's optimizing mixing performance, enhancing dispersion, or maximizing throughput, every aspect of the conveying element's design is fine-tuned to achieve optimal results.Operational Mechanisms

The operation of the conveying element is governed by the principles of intermeshing screws and counter-rotating motion. As the screws rotate in tandem, the helical flights engage with the material, propelling it forward along the screw channels. This continuous conveying action ensures thorough mixing, efficient heat transfer, and precise control over residence time—a trifecta of benefits essential for demanding industrial processes.Versatility and Adaptability

One of the defining attributes of twin screw systems is their unparalleled versatility, and the conveying element is no exception. Whether it's handling powders, granules, pastes, or viscous slurries, twin screw systems equipped with the right conveying elements can tackle a diverse array of materials with ease. This adaptability makes twin screw systems indispensable across a myriad of industries, from food and pharmaceuticals to plastics and chemicals.In summary, understanding the nuances of the conveying element is key to unlocking the full potential of twin screw systems. By appreciating its functionality, design considerations, and operational mechanisms, engineers and operators can harness the power of twin screw technology to achieve unparalleled levels of performance and productivity.

Prev News Next News

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-