Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Single-stage EX-150 Spiral Ceramic Extruder

A. Features EX-150 Spiral Ceramic Extruder

Six years ago, we introduced and optimized the improved German spiral ceramic film extruder technology to meet the urgent needs of Chinese water treatment industry users. In addition to using more cost-effective manufacturing parts, the fully domestic extruder optimizes the replacement structure design of the breakable parts module to facilitate the daily maintenance of the extruder, optimizes the design of the vacuum exhaust structure of the extruder and eliminates the defects of the agglomeration and drying of the materials which affect the product quality.

Our company pursues the extruder design on the basis of high cost-performance and lower energy consumption. At the same time, we insist on the pursuit of high stability and reliability of the extruder operation process, the intuitiveness and convenience of extruder control, the convenience of daily maintenance. For this purpose, we have adopted supporting designs such as energy-saving frequency conversion control of the motor, PLC control system, and modular core components. We give full play to our company's first brand advantage in the service life of the heart parts of extruders in China, the barrel and screw of extruder core parts are made of special 1.4112 martensitic stainless steel, which has achieved ideal performance of high corrosion resistance and wear resistance, achieves the goal of longer extruder running time.

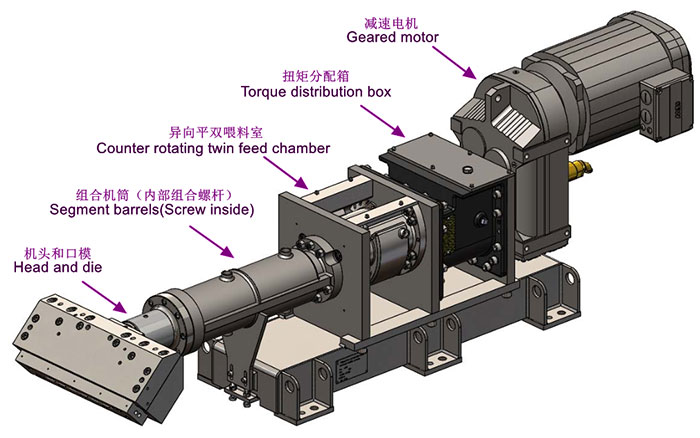

B. Composition of EX-150 spiral ceramic extruder:

C. Structure features of single-stage EX-150 ceramic extruder:

1. Length to diameter ratio(L/D) and motor power of the extruder:L/D6.3, motor power22kw. It is specially designed forrunning ceramic raw materials which are generally with the moisture content less than 10% or about;

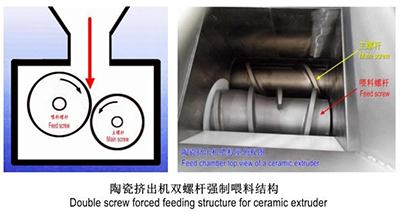

2. The extruder feeding section is equipped with a counter screw feeding system designed for the characteristics of ceramic mud. Different from extrusion of high polymer materials, ceramic mud is generally mixed with organic cellulose with high proportion as the adhesive. The mud has certain water content and mutual adhesion "agglomeration", with very poor liquidity, resulting in difficult feeding of extruder. Therefore, the extruder feeding system adopts a special inward "double wrist" structure design, as shown in the right figure, to realize the forced feeding function of ceramic mud;

3. When ceramic materials are operating inside the extruder barrel, there is a very obvious feature that is completely different from other operating materials. That is, the hard solid phase ceramic materials will generate serious "shear force" when contacting with the barrel inner wall and the screw, and the shear force will generate very high "shear heat". However, there is a certain component of organic cellulose as an adhesive in the ceramic material. Once these organic cellulose decompose after withstanding high shear heat, its function as an adhesive will be greatly reduced or even destroyed.

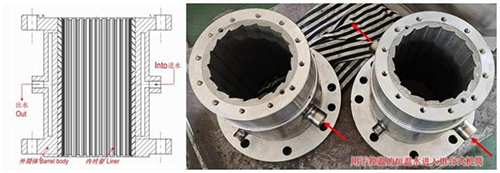

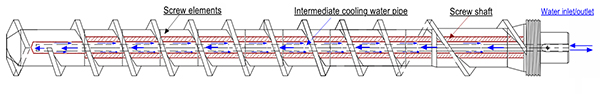

In order to avoid this "thermal decomposition", in addition to minimizing the "shear heat" in the structural design of the screw, the modular barrel of the ceramic extruder and the core of the screw are both designed with a forced water cooling circulation system. In combination with the circulating constant temperature water input from the external high-power chiller, the ceramic material is forced to cool to the appropriate temperature required for its operation, Realize precise temperature control of the material temperature inside the extruder.

The water circulation system inside all the barrels of the ceramic extruder is designed as shown in the below right figure.

The barrel of the double-stage cylinder is made of 304 stainless steel to prevent the corrosion of condensation water, especially in summer. The cylinder liner is lined with segmented, hardened 1.4112 (corresponding to Chinese grade 9Cr18MoV) martensitic stainless steel inner liner to resist the extremely severe friction wear and acid-base corrosion wear of ceramic materials mixed with organic cellulose.

The modular threaded components are connected to the shaft through splines andget the power torque transmitted by theshaft. Inside the inner of the shaft is installed with a stainless steel pipe, and circulating constant temperature water is sprayed out of the steel pipe and flows back along the inner wall of the shaft,take away the shear hot received by the material, as shown in the following figure:

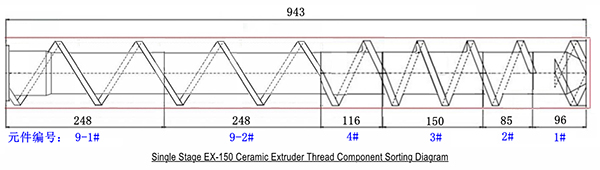

4. Ceramic "mud" in the solid phase with a high shear extremely severe friction on the extruder core components, and the high water content of mud has high acid and alkaline corrosion, so the working conditions of ceramic extruder is extremely harsh. To ensure the high stability and reliability of the EX-150 ceramic extruder during the production process, our company takes advantage of our first brand of extruder core parts research and development advantages in China, not only to use the more cost-effective martensitic stainless steel for threaded components, but also we can provide parts made of powder metallurgy high-temperature isostatic pressing materials to help users extend the service life of the extruder. In addition, the core parts of the barrels and screws are modular design and manufacturing, in order to facilitate user replacement, reduce the maintenance cost of the extruder. Once the extrusion output drops, the product molding is unstable, the user only needs to replace the parts with severe local wear, which can quickly resume production.

The following diagram shows the screw design structure and modular thread element code of EX-150 ceramic extruder:

The above modular screw components are made of special wear-resistant and corrosion-resistant martensitic stainless steel, and the ultimate quenching hardness can reach HRC 62 or above;

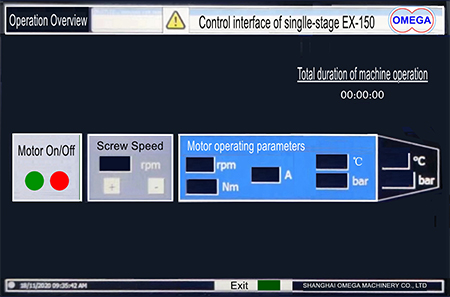

5. In order to meet the user's requirements for various products molded by ceramic extruder, including high dimensional accuracy requirements for extruded diaphragm (pipe) products, the control system configured for ceramic extruder needs to realize the strictest feedback and closed-loop control for the pressure fluctuation range of operating materials. In order to achieve this purpose, ceramic extruder adopts PLC programmable logic controller host to precisely control the screw speed by the main motor, that is, to realize the accurate PID setting linkage closed-loop control of the main motors of EX-150 extruder. All these controls can be intuitively operated through the 10-inch touch screen installed on the site.

For this purpose, a high-end American DYNISCO brand pressure/temperature dual sensor is configured in front of the forming template to accurately feed back the pressure and temperature information of the material in front of the head(see right above), so that the closed-loop control system can more accurately and timely strictly monitor the dynamic online status of the material, as shown in the right figure.

6. In order to ensure the high reliability and stability of the operation of the machine, while pursuing the minimum energy consumption during operation, the main motor of EX-150 extruderis of high-end Shanghai Haoguan brand and the supporting domestic Jiale variable frequency governor, and the accurate and reliable variable frequency speed regulation mode is adopted. In this way, the screw speed can be controlled more strictly so as to achieve accurate control of product size, energy conservation and consumption reduction.

D. Main technical parameters of EX-150 spiral ceramic extruder:

|

Feeding system |

80L volume 304 stainless steel hopper, counter rotating feed screw provide a more positive feed and consistent flow of material |

|

Main Motor and Power |

High reliable variable frequency gear motor of China with 22 kw |

|

Screw diameter (mm) and manufacturing material |

¢150,1.4112 martensitic stainless steel, the hardness after quenching is HRC 55~60 |

|

Screw ratio (L/D) |

6.3 |

|

Screw Speed (Wax.) |

30rpm |

|

Screw maximum thrust(Max.) |

14.5Mpa |

|

Bearing torque (Max.) |

7000Nm |

|

Temperature control way |

Constant temperature and soft water circulation inside both barrel and screw |

|

Temperature control range |

10℃~50℃ |

|

Temperature control section for barrel |

2 Sections |

|

Head pressure measurement and feedback |

Equipped with American DYNISCO brand pressure sensor, with measuring range of 5000PSI |

|

Screw center height |

800mm |

|

Extrusion yield range |

150kg~200kg/hr, based on the ceramic raw materials with a powder packing density of approximately 2.5g/cm3, output varies with the ceramic formula (such as silicon carbide、cordierite、porcelain and aluminum oxide, etc.) and also varies with the mold product type |

|

Total installed capacity(kw) |

~35 |

|

Electricity consumption in normal production |

80% |

|

Exterior dimensions |

L2100mm×W760mm×H1100mm(Hopper height not calculated) |

|

Full Weight(kg) |

1800 |

D. Configuration and characteristics of EX-150single-stage spiral ceramic extruder

Chief Engineer Office / Shanghai Omega Machinery Co., LTD.

- Information

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- What countermeasures can be taken to improve the dimensional and positional accuracy of profiles during the profile production process?

- How should profile molds be cleaned and maintained?

- What are the corresponding solutions to the phenomenon of grooves and pits on the surface of profiles?

- How should the raw materials be selected in the formula for PVC surface skin core layer microcellular foamed extruded profiles?

- How should the production process of biaxially oriented polyethylene terephthalate (BOPET) film be controlled?

- How should the longitudinal and transverse stretching be controlled when producing biaxially oriented films by the flat film method?

- How should the counter-rotating conical twin-screw extruder be operated for no-load test run?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-