Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

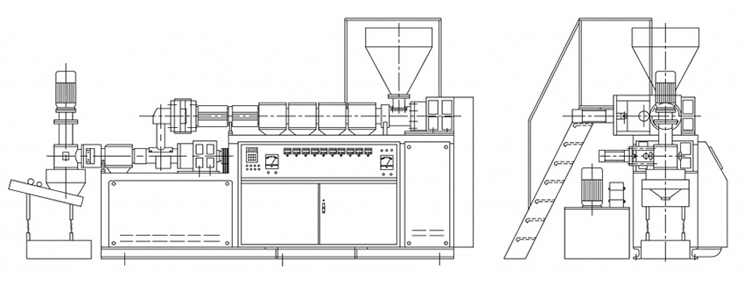

How does a single screw extruder work?

Jan 18,2021

The efficient operation of a single screw extruder requires that all three extruder sections, solids conveying, melting, and metering, must be designed to work efficiently and in coordination to have a trouble-free process. The simple flow calculations for the metering section should be performed at the start of any extruder troubleshooting process.

First, Feeding the resins or pellets

A polymer, as powder or pellet, is continuously fed from the hopper into the extruder barrel.

Second, Melting of the resins

The heated barrel melts the polymer and transports the material through the die.

Third, Actual extrusion process

The screw channel exerts the force on the polymer by the rotating screw while the stationary barrel gives a breaking force to the rotating polymer and makes the polymer slip slightly on the screw surface.

Fourth, Cooling it down

After passing through the die, your plastic passes through the cooling zone.

Fifth, Final finishing procedures

Involves putting the final touches on your plastics. This includes drilling, printing, bending or cutting.

Omega specializes in the production of custom-made single screw extruder. Our company has a specialized team to design and manufacture the first-class yet reasonable price of the single extruder as per overall specifications of our clients and ever-increasing industrial requirements. We invest in advanced and safe resources with an aim to improve the rate of efficiency of our production. You can feel free to contact our company at any time you like to prefer and invest in one of the most appropriate single extruders.

Prev News Next News

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-