Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

How to Renew a Segment Barrel

A. By analyzing the existing problems of Parallel Twin-screw Extruder Barrel, we aim at putting forward targeted renovation scheme, to recover and strengthen the segment barrel function.

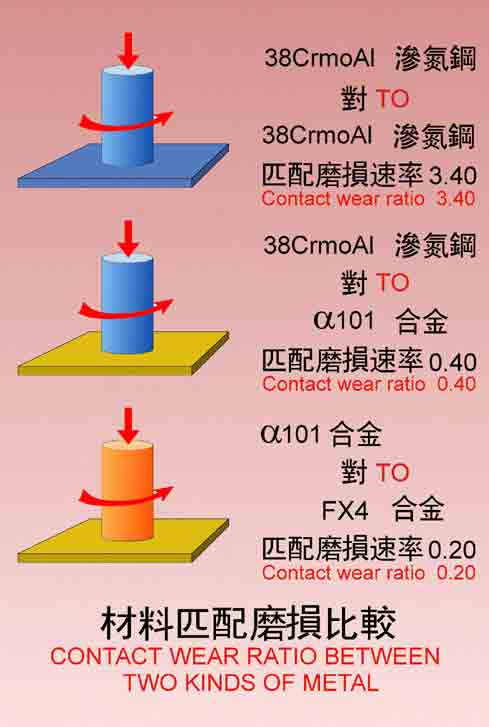

About the current Parallel Twin-screw Extruder Barrel and screw components, we think there is irrationality when some retailer selects materials. Theoretically, contact wear or matching wear between the work pieces made from the same material and processed by the same hardening means can easily cause physical loss between the components. The situation in the heart of parts of the Reactive Parallel Twin-screw Extruder, the barrel and screw components are especially apparent. Because in the Reactive Parallel Twin-screw Extruder, the friction between the outside diameter of the screw thread and the inner wall of barrel, are more direct and serious. If the original extruder barrel and screw components are both made from the steel 41CrAlMo7 material (This is the standard name of GERMANIC, and also the standard name of 38CrMoAl steel in Chinese steel), and both adopt the hardening method of gas nitriding in the surface, and then because of the matching of the material, the attrition will be more serious. The picture on the right can give us an intuitive meaning.

Therefore, in the renovation of this kind of Parallel Twin-screw Extruder Barrel, what we should consider upmost is to use a liner inside the barrel made from a different material from the screw components. For example, we can adopt overall steel liner made from Omega 101A which is a kind of high wear resistance materials casted by the iron-based powder metallurgy PM–HIP way. It will largely reduce the matching wear between the materials, thus the working life of the barrel and the screw component can be extended to a great extent. Therefor after renovation, the Parallel Twin-screw Extruder can work in the secure and guaranteed operating state.

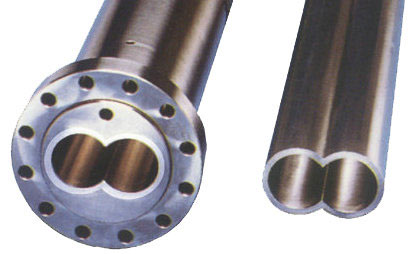

Our company is the first manufacturer of the high wear resistance, high corrosion resistance, and both resistances Oval Liner for the Twin-screw Extruder Barrel adopted the method of iron-based powder metallurgy PM–HIP in recent years in Chinese mainland. This product is the only one which received the quality recognition of the authority company Werner & Pfleiderer GMBH - Germany (W&P) and qualified supplier. 101A oval liner material adopted the method of Powder metallurgy PM - HIP is numbered as 1.2292.2 according to German W&P Company. The German specific material is named as G-X 250CrV25, also known as GP27M and the corresponding material name in the company is Omega 101A.

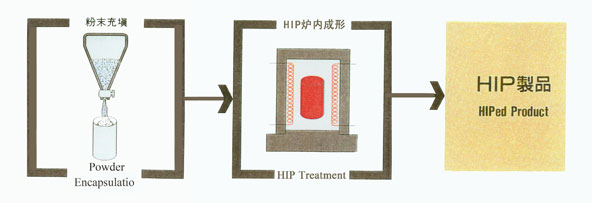

The material 101A is one kind of iron-based high wear resistance alloy material with the carbide silicon, carbide manganese, carbide chrome and other different kinds of fine carbide particles evenly distributing in the base material of iron which can be resistant to wear and tear. Our company using PM - HIP metallurgy adopted high temperature static pressure technology fills the specific mold cavity with the improved German high wear resistance and low expansion alloy powder material, and then put it into the high temperature static pressure furnace. In the high temperature and high pressure environment, the material molecules accelerated motion by strong extrusion, thus after cooling the metallographic structure high density and excellent wear resistant cylinder overall alloy lining set (the picture on the below) can be produced. The technology has filled the blank of adopting the hard technology in producing heart parts of the Parallel Twin-screw Extruder Barrel in China, satisfying the industry needs and expectations.

With PM-HIP production process,the standard macro-hardness value of the wear-resistant Oval Liner Omega 101A reaches HRC 58~64. We also provide to customers Cobalt-based Oval Liner Omega 301A with Rockwell hardness over 50, featuring its well anti-corrosive wearability.

Currently, a replaceable liner to be used for maintain the parallel twin-screw extruder barrel. There are two kinds of neck bushes available: one is two bimetallic liners with C form for butt joint (See right-hand picture); Another way, as stated above, is an ellipse Oval Liner. The reason why we put Oval Liner as the recommended is to avoid the inner disadvantage of the two C-bimetal-bushing, for the stress concentration at the sharp corners of“C”lining process can easily lead to crack in relatively fragile alloy layer, which will further damage the alloy layer of inner hole face .There are other problems lie in the alloy layer of bimetal neck bush, such as thickness limit, possibilities of gas erosion in axial joint from heated Polymer Material.

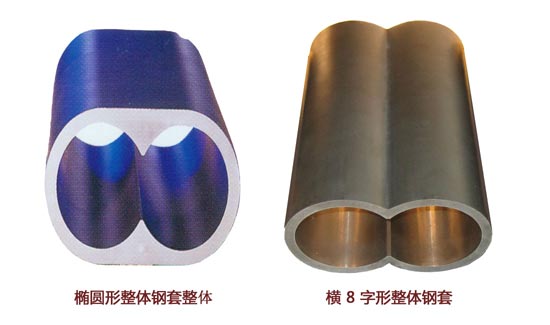

PM-HIP Oval Liner, casting in the powder metallurgy way, resulted to two basic shapes, one is in elliptic shape, and the other is in horizontal“8”shape, as illustrated in right. If the cooling runner structure of the barrel allows, the elliptical Oval Line is highly recommended, to be used as neck bush in a barrel. The reason still lies in avoiding possible damages from stress concentration at the two sharp corners of the neck bushes. Adoption of elliptical Oval Liner as core component in Parallel twin-screw extruder barrel by European manufacturers is also based on this consideration.

B. Introduction of our maintenance and reconstruction process for Segment Barrel

Maintenance and reconstruction process for an segment barrel can be divided into three steps: First step is to buy a matched segment Oval Liner; Second is to enlarge original bore to be a necessary size, keeping the original center distance of two bores; Third is to put the liner into the segment barrel, fix it and make feeding hole if necessary.

Verticality of the end face must be checked after one Oval Liner is lined into the barrel. With verticality ensured, two end faces of the Oval Liner have to be grinned. Since thermal expansion coefficients of multiple component powder metallurgic steels Omega 101A features 10.0×10-6, which is a little lower than common mid carbon alloy steel at 15℃~250℃, then the Oval Liner has to left a little longer out of the barrel during grind of face ends. The length of which will decided by the final data based on scale model experiment of the two materials.

Final detection is always carried out for the segment barrel when maintenance and reconstruction work has done. In addition to stress testing for the cooling runner at every barrel section, linearity surveying has to follow, measuring by special linearity testing core rod with normal working conditions after the segment barrels is integrated axially.

Chief Engineer Office

Shanghai Omega Machinery Co., Ltd.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-