Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

How do you make a twin screw extruder?

Apr 10,2024

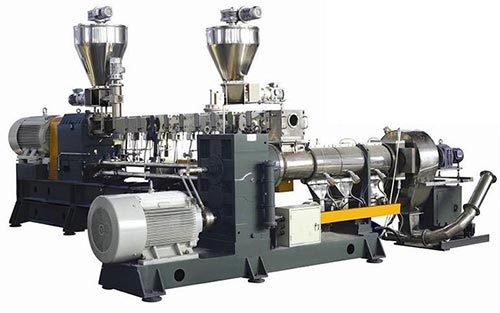

Design: Start by designing the extruder. This involves determining the specifications such as the diameter and length of the screws, the material of construction, the heating/cooling mechanisms, and the overall configuration of the machine.

Screws: Twin screw extruders have two intermeshing screws that transport and mix the material. These screws are typically made from high-strength materials such as steel or alloy. They need to be precisely manufactured to ensure proper functioning.

Barrels: The screws rotate within barrels, which also need to be carefully designed and manufactured. The barrels are often heated to melt the material being processed, so they may have heating elements or jackets to regulate temperature.

Feeding System: Materials are fed into the extruder using a feeding system. This may involve hoppers, feed screws, or other mechanisms to ensure a consistent flow of material into the extruder.

Heating and Cooling: Depending on the materials being processed, heating and/or cooling systems may be required to control the temperature within the extruder. This is crucial for achieving the desired properties of the extruded material.

Control System: An electronic control system is needed to monitor and adjust parameters such as temperature, screw speed, and material flow rate. This ensures consistent performance and quality of the extruded product.

Assembly and Testing: Once all components are manufactured, they need to be assembled into the final extruder machine. Extensive testing is necessary to ensure that the extruder operates correctly and produces the desired results.

Building a twin screw extruder requires advanced engineering skills and access to specialized manufacturing equipment. It's not something that can be easily done without proper expertise and resources.

Prev News Next News

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-