Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Overall Steel Sleeve Tolerance and Detection

Aug 01,2016

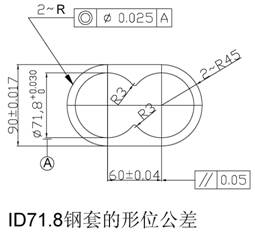

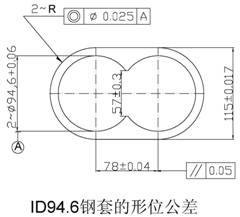

1.1 In addition to the necessary dimensional tolerances, each specification steel sleeve geometric tolerances controlled by mainly two conditions: concentricity of two parallel bore with two remote ovals outside the park, and the parallelism of two holes, below are ID71. 8 and ID94.6 end view of the steel sleeve. If steel sleeve concentricity guaranteed, means steel sleeve symmetry controlled; steel sleeve parallelism once determined, also means the determination of steel sleeve two holes center distance.

1.2 After steel sleeves coming into the machine barrel, you also need to measure the cylinder bore and verticality of barrel end face.

2. Steel sleeve detection and major measure tool

2.1 Detection of steel sleeve, in addition to the measured steel sleeve relative size tolerance, the focus should be on the first item which mentioned two geometric tolerance test;

2.2 Detection of steel sleeve, commonly used standard measure tools are the tour dial calipers, bore gages, 0 ~ 25mm thickness micrometer and dial indicator;

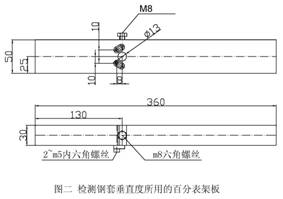

2.3 In addition to the above standard measure tools, it still need to make a steel sleeve with a dial indicator to measure the degree of vertical-specific accessories "dial shelf board" and "foot", as shown above.

3. Steel sleeve main detection methods

3.1 Steel sleeve two parallel bore size detection method: in the steel bushing hole’s left, right, top and bottom select multiple measurement points, respectively by the table diameter measurement measure the steel sleeve hole size.

3.2 Steel sleeve concentricity measurement: with wall 0 ~ 25mm thickness micrometer detecting steel sleeve oval two remote multi-point wall thickness outside the park condition, you can understand steel housing bore and the concentricity situation of the outside the park.

3.3 Steel sleeve parallel measurement commonly use contrast method: that is use a dial indicator in the farthest point of the hole across two upper and lower ends, respectively measure parallel of steel housing bore (see right picture).

Steel sleeve hole and the steel sleeve end verticality measurement: with self-made dial indicator holder, put pressure on the end surface (see figure V), respectively force uniform wall steel housing bore distal, read the difference values, it is steel sleeve does not sag values.

4.1 barrel inner holes and steel sleeve elliptical peripheral installation tolerances are recommended for: H7 / js7.

4.2 Steel sleeve pressing into and extrusion, generally, it requires using 10 tons vertical hydraulic machine, hydraulic press to a plane parallelism error of clamp, requires no more than 0.10 mm.

4.3 When original bushing press out, the cylinder liner below shall be put different thickness parallel blocks in order to stay out vertical space of as bushes pressed out; while the top of the cylinder liner shall bushing slightly smaller than the circumference of a and a height slightly larger than the bush, and sufficient strength parallel iron, using a hydraulic press gently press out the original bushing.

4.4 If the original barrel adopts whole steel sleeve, and interference with the steel sleeve "locking", it can’t simply use the hydraulic methods above. Before the barrel put on hydraulic machine, it must also use line cutting method to cutting a line or a gap in the direction of 180 degrees of original steel sleeve, and then use the hydraulic machine press original steel sleeve out.

Pressed into new steel sleeve, thermal sleeve is generally recommended method. Barrel heated to about 200 ~ 250 ℃, then put steel sleeve gently into the elliptical cylinder bore, on the condition of steel sleeve longer than barrel end surface with appropriate length, let barrel to cool to room temperature, which has a barrel "lock" effect of the steel bushing.

5. When the steel sleeve put into, it still needs to grind barrel two end faces

5.1 When machine barrel cooling to room temperature, it must grind two end face of the upper and lower, generally it should use the M7130 surface grinding machine.

5.2 Grinding steel bushing need synthetic diamond grinding wheel, which is also called JRC grinding wheel, size of 60, concentration 75%.

5.3 In the process of the machine barrel first end face grinding, it needs many times according to the above mentioned in item 3.4 "special dial indicator holder " measuring steel sleeve verticality method, to check the barrel bore verticality by random. With the method of the check and adjustment, we commonly called "fixed grinding method". Verticality measurement by two to edge value subtract the difference, large side means needing to correct grinding position, grinder needs at the bottom of this needs sharpening place put proper thickness mat of the gasket, fixed grinding machine end face, and according to this method, the end surface grinding machine barrel gradually to the inner hole two pairs of edge size consistent.

5.5 Grinding the barrel of the second end surface, after barrel with turn 180 degrees install in grinding work surface after grinding the long straight out of the barrel of the steel sleeve ends, to its original barrel end face basic connection flat.

Shanghai Yuankang Machinery Equipment Co., Ltd.

Chief engineer office

- Information

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-