Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

COEX-120-2 Double-stage Ceramic Extruder

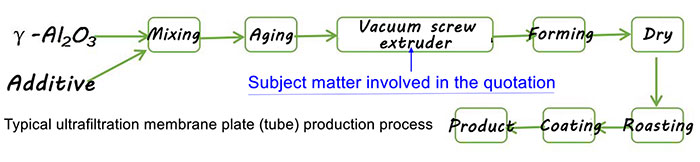

A. Ceramic ultrafiltration membrane product

Ceramic ultrafiltration plate membrane can effectively remove organic matter, suspended matter, toxic and harmful substances (such as radium, arsenic), micro organism, algae and oil in liquid, and is the core and key component of new efficient separation technology. It is a kind of ultra-fine filter membrane with asymmetric structure, which is prepared by sintering process with inorganic materials such as alumina. Compared with the traditional organic membrane, it has the advantages of good chemical stability, good reliability, long service life, small occupation space, excellent pollution resistance and low energy consumption, which represents a development trend of water treatment membrane materials.

The service life of ceramic flat film is 3~5 times longer than that of polymer film, the membrane flux is 3~10 times higher, the consumption of chemical agent is reduced by 50 times, the cost of operation and maintenance and energy consumption are reduced by more than 50%. the contamination, chemical cleaning and oxidation of polymer ultrafiltration membranes are an inevitable conundrum, while ceramic membranes are easier to clean, more resistant to contamination, and there is no risk of oxidation.

Our company overcome difficulties, based on German EAC-Elektro company alumina ceramic membrane extruder technology of double-stage vacuum exhaust spiral ceramic ultrafiltration membrane extruder model VAHRS 120B, to meet the needs of domestic users. Not only we use better cost-effective manufacturing materials that our extruder could be cheaper, but also we have further developed the technology of ceramic extruder, such as we fully localized extruder optimizes the structural design of the replacement module and facilitates the maintenance of the extruder, and the vacuum chamber structure design is optimized to eliminate the defects such as possible leakage pressure due to deformation. Therefore, the extruder is superior to imported extruder in some performance.

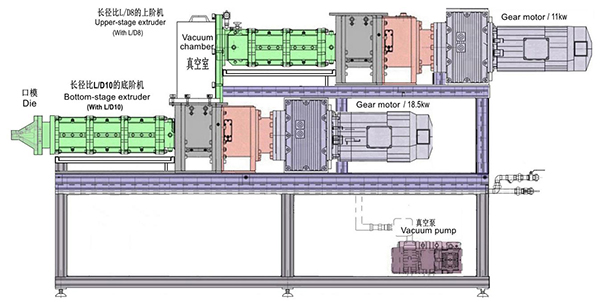

B. Structure diagram of COEX-120-2 Double-stage ceramic extruder

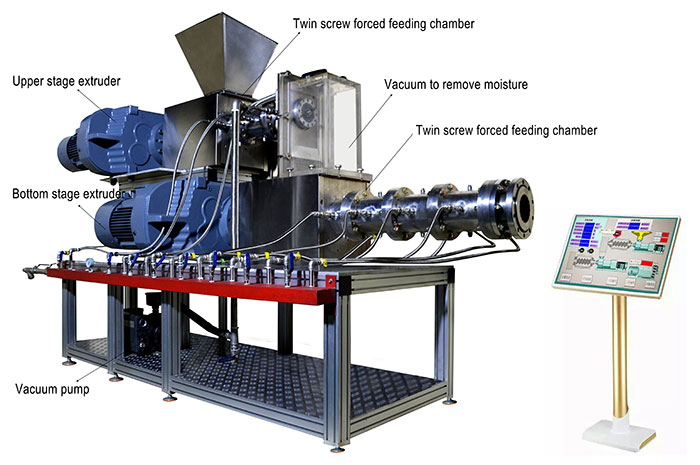

C. Main structure of double-stage COEX-120-2 ceramic extruder:

D. Structure and configuration features of double-stage COEX-120-2 ceramic extruder:

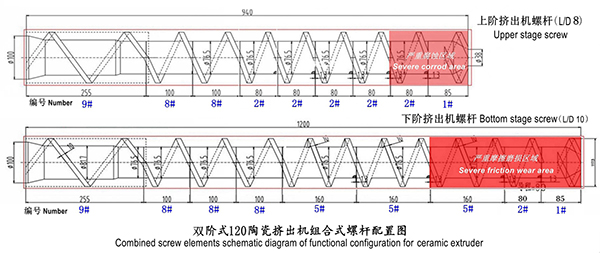

1. Length to diameter ratio(L/D) and motor power of the extruder:

A. The upper-stage machine L/D8, matched motor power11kw;

B. The lower-stage machine L/D10, matching motor power18.5kw;

2. COEX-120/120 double-stage ceramic extruder is specially designed for high-water content inside the ceramic raw materials, a vacuum exhaust system with high intensity for water removal is designed, that is, the materials are extruded from the upper-stage machine into a "vacuum chamber" with negative pressure inside, and the negative pressure in the vacuum chamber is adjusted underavisible and quantifiable conditions, so as to realize the quantitative water removal function, as shown in the right figure.

The negative pressure vacuum chamber from the upper stage machine to the lower stage machine can be opened or the required vacuum negative pressure value can be determined by the user according to the on-site production requirements, such as the water content of the product and other standard requirements to remove the required quantitative water. Under the closed state of negative pressure, the vacuum chamber provides a channel for the materials mixed in the upper stage machine to smoothly enter the lower stage machine under the condition of no loss of moisture, so as to achieve further fine mixing and pressurization functions.

The vacuum chamber of the extruder is made of transparent acrylic materials to facilitate the on-site operators to intuitively and accurately control the material vacuumization;

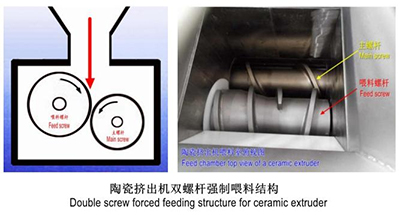

3. The feeding section of the upper and lower extruders of the double-stage extruder is equipped with a counter screw feeding system designed for the characteristics of ceramic mud. Different from extrusion of high polymer materials, ceramic mud is generally mixed with organic cellulose with high proportion as the adhesive. The mud has high water content and mutual adhesion "agglomeration", with very poor liquidity, resulting in difficult feeding of extruder. Therefore, the two-stage feeding system of ceramic extruder adopts a special inward "double wrist" structure design, as shown in the right figure, to realize the forced feeding function of ceramic mud;

4. When ceramic materials are operating inside the extruder barrel, there is a very obvious feature that is completely different from other operating materials. That is, the hard solid phase ceramic materials will generate serious "shear force" when contacting with the barrel inner wall and the screw, and the shear force will generate very high "shear heat". However, there is a certain component of organic cellulose as an adhesive in the ceramic material. Once these organic cellulose decompose after withstanding high shear heat, its function as an adhesive will be greatly reduced or even destroyed.

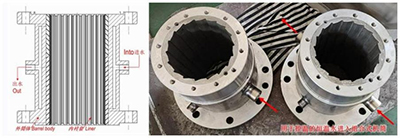

In order to avoid this "thermal decomposition", in addition to the structural design of the screw to minimize the "shear heat", the upper and lower stages of the two-stage ceramic extruder are all designed with forced water cooling circulation system inside the modular cylinder. Under the cooperation of the circulating water input by the external high-power water chiller and set as the temperature required for the operation of ceramic materials, Realize accurate temperature control for the material temperature in the extruder.

The water circulation system inside the double-stage cylinder of the ceramic extruder is designed as shown in thebelow right figure.

The barrel of the double-stage cylinder is made of 304 stainless steel to prevent the corrosion of condensation water, especially in summer. The cylinder liner is lined with segmented, hardened 1.4112 (corresponding to Chinese grade 9Cr18MoV) martensitic stainless steel inner liner to resist the extremely severe friction wear and acid-base corrosion wear of ceramic materials mixed with organic cellulose.

5. Aiming at the characteristics of high acid and high alkali corrosion working conditions of ceramic raw material formula, the extremely serious friction and wear characteristics of ceramic "mud" under high shear of solid phase, and the acid and alkali corrosion characteristics of high water content of mud, the core components of ceramic extruder are of convenient and more interchangeable modular design. Once the extrusion output is reduced and the extrusion product is unstable and the parts need to be replaced, the user only needs to replace the parts with serious local wear to reduce the operation cost of the extruder and quickly restore the production.

The following diagram shows the screw design structure and modular thread element code of COEX-120/120 ceramic extruder:

The above modular screw components are made of special wear-resistant and corrosion-resistant martensitic stainless steel, and the ultimate quenching hardness can reach HRC 62 or above;

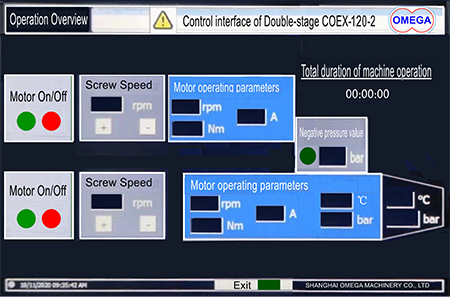

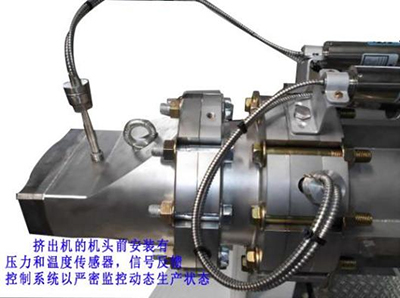

6. In order to meet the user's requirements for various products molded by ceramic extruder, including high dimensional accuracy requirements for extruded diaphragm (pipe) products, the control system configured for ceramic extruder needs to realize the strictest feedback and closed-loop control for the pressure fluctuation range of operating materials. In order to achieve this purpose, ceramic extruder adopts PLC programmable logic controller host to precisely control the screw speed output by the secondary main motor, that is, to realize the accurate PID setting linkage closed-loop control of the two main motors of COEX-120/120 extruder from the upper to the lower. All these controls can be intuitively operated through the 10-inch touch screen installed on the site.

For this purpose, for thelower-stage machine directly acting on the forming, a high-end American DYNISCO brand pressure/temperature dual sensor is configured in front of the forming template to accurately feed back the pressure and temperature information of the material in front of the head, so thatthe closed-loop control system can more accurately and timely strictly monitor the dynamic online status of the material, as shown in the right figure.

7. In order to ensure the high reliability and stability of the operation of the machine, while pursuing the minimum

For energy consumption during operation, the upper and lower main motors of COEX-120/120 extruder are of high-end Shanghai Haoguan brand and the supporting domestic Jiale variable frequency governor, and the accurate and reliable variable frequency speed regulation mode is adopted. In this way, the screw speed can be controlled more strictly so as to achieve accurate control of product size, energy conservation and consumption reduction.

E. Main technical parameters of COEX-120-2 Double-stage ceramic extruder:

F. Configuration and characteristics of COEX-120-2 Double-stage ceramic extruder:

We make the COEX-120-2 Ceramic plate (tube) extruder, the first pursuit of configuration is the stability and reliability when the extruder in process. The second goal is to give full play to the advantages of our first brand of extruder heart parts in China, we use the PM-HIP stainless steel imported from Europe to get a high corrosion resistance and high wear resistance feature, to get a longer service life of extruder. Modular design is used in the designing of core components to facilitate the replacement of easily damaged parts and reduce the maintenance cost of extruder.

According to the above ideas, ourCOEX-120-2 ceramic extruder configuration as follows:

Chief Engineer's Office / Shanghai Omega Machinery Co., Ltd

- Information

- During the production of cross-linked polyethylene cables, early cross-linking often occurs. What causes this phenomenon and how can it be solved?

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-