Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Several advantages of bimetallic barrel

Dec 11,2017

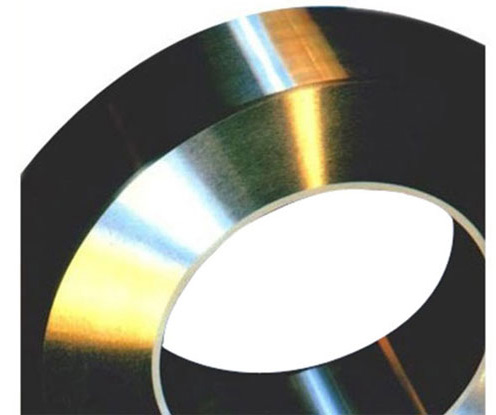

There are several advantages of bimetallic barrel that helps to enhance the wear life and maximize the incredible process performance. However, the design of bimetallic has provided the optimum transfer of energy between bore and backing material. The most exciting features of bimetallic barrel are excellent engineered design, undividable inlay bond, bimetal construction, bimetallic bore inlay, improves withstand power and also high performance as well. These are all features of construction via bimetallic barrel and let’s take a look at those benefits as well. It is also important to have very good understanding of its operation.

- Information

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- What countermeasures can be taken to improve the dimensional and positional accuracy of profiles during the profile production process?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-