Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Technical Proposal Of PET Flake Granulation Line

1. Material System And Process Requirements

1.1. Product application direction: Suitable for recycle PET flake granulation;

1.2.General situation of raw material system:No particular requirements of material system for explosion proof, corrosion, etc.;

1.3. Basic process requirements: §

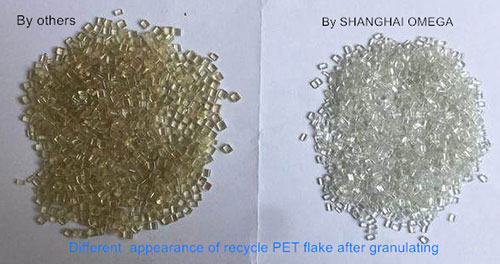

1.3.1 Therecycle PET flakes is plasticized, mixed and discharged through a twin screw extruder, together with professional whitening agent, transparency enhancer(Show right), viscosity enhancer(The viscosity of regenerated particles of the bottle tablet reaches about 0.65, not any complicated pre-crystallization drying system is required)and toughening additives if any needed;

1.3.2 After passing a die head, PET material is to be stripped, into a water tank to be cooled, then afterdrying, hauling and granulating.

2. Complete Unit ProductionCapacity §-

2.1 PET materialroot number(Max.); ¢3.0×19;§

2.2 Maximum hauling speed; 90M/Min;§

2.3 Maximum output of complete unit: 450kg/h, it varies according to the size, the chip type and the unit volume ratioof PET flake material;

2.4 Different PET material varieties, the different melting index yield;

3. Brief Description of Process Configuration Scheme

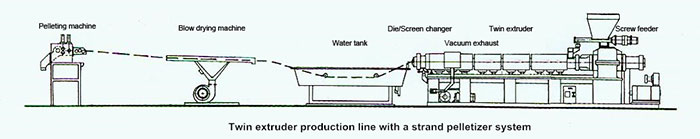

3.1 Complete unit flow chart

The whole unit can be roughly divided into raw material metering unit, mainframe system, granulation system, electric instrument automatic control system, flow chart as follows:

3.2. Brief introduction of each component in the process is as below:

Remark: PET is a thermally sensitive material, which solidifies rapidly when be cooled. Otherwise the flake of carbonated soft drink, with special viscosity and melting index, so a strip way by the water cooling generally to be used. An under water palletizer way is not recomended.

3.2.1 Raw material metering unit

--The recycle PET flakes premixed with kinds of additives afore mentioned in a hopper and than to beand then fed into the twin-screw extruder byone single screw feeder. §

3.2.2 Twin-screw host system

- According to the requirement of material technology and production capacity, a SHJ-75/600-160-40 machine is recommended for twin screw mainframe;

3.2.3 Other auxiliary:

--Strip water cooling system: Sufficient cooling of thePET stripby water;

--Strip drying system: Water on the surface of the strip after cooling by blowing dry water to reduce the moisture content of the finished product grain as far as possible;

--Dicing cutter: The traction roller and the cutter are driven by a single motor, and the requirements of the finished product particles of different lengths are realized by matching different frequency conversion speed;

--Oscillating screen:A disqualified particle after being separated from a grain; §

3.2.4 Electronic automatic control system

--The whole set of units adopts the newly developed intelligent control mode;

--Thefeed quantity, thetraction speed of strip, and the speed of granulatorcan be controlled by linkage;

--The whole equipment adopts PLC control mode.

4. Range of Equipment Supplied

4.1 The range of supply included in the quotation for this complete set of equipment: From a screw feeder toavibrating screen;

4.2 The seller shall be responsible for the supply of wire and cable from the electric meter cabinet to all the parts listed in the scope of supply and the wiring of the site, including the cable bridge or cable trench, The buyer shall be responsible for the on-site electrical engineering supporting facilities for ground wire laying and the input power supply of the seller's electric meter cabinet;

4.3 The buyer is responsible for the necessary public works such as grain cutting cooling water, instrument compressed gas and so on for the unit, and the seller is responsible for providing the relevant interface position and parameter conditions;

4.4 The buyer shall be responsible for the hoisting position of the unit at the site of the buyer and the relevant handling of the ground foundation.

5. Twin Screw Extruder And Granulation System

5.1. Screw feeder

* Special to be designed and suitable for PET flakes;

* Hopper; 150L, Made from stainless steel 304;

* 1.5KW AC frequency conversion motor, adopting Miyakawa Yuriyasu“YOLICO” brandfrequency converter in Japan, reducer speed ratio: 11:1;

* Feeding motorjoints to reducer with direct coupling, using Intermeshing twin screw feeder, feedingina smooth and uniform way.

5.2.Co-directional twin-screw extruder

5.2.1 Main basic technical parameters of Twin Screw Extruder with model SHJ-75/600-160-40

* Twin-screw diameter; ¢71.6mm;

* Extruder L/D ratio:40;

* Twin-screw speed(Max.): 600r/min

* Screw diameter / inner diameter ratio: DO/Di=1.51;

* Main motor power: 160kw(AC variable frequency speed regulating);

* Total heating power:~65kw

* Total power of machine assembly: ~240kw;

* Unit total weight: ~5.8 T;

* Extruder center height:1200 mm;

* Unit shape dimension(L xW x H): ~160000mm x850mm x1700mm(Except hopper);

5.2.2. Mainframe barrel

* The mainbarrels is designed according to the building block principle. Each unit section usually has the same length and interface form;

* The length to diameter ratio of each unit of standard type is:L/D=4;

* The external electric heater of eachbarrel unit (Except the feedbarrel) is provided with a soft water cooling channel, which can realize the independent heating and cooling temperature control of eachbarrel unit;

* Bimetallic liners inside each barrel bore with highwear-resistance alloy protective layer, the layerhardness isHRC 58~64,and its thickness is1.5mm over;

* The machine consists of 10 sections ofbarrel, one is for feeding, one section of natural exhaust, and one section of vacuum exhaust, other seven sections are closed;

* Stainless steel protective cover on the outside of cylinder body, with the function of heat insulation and safety protection, etc.;

* All the tubes and connectors are made of the first-class CNC machining center in China, and the manufacturing precision is up to the advanced level in the world.

5.2.3 Mainframe screw

* The screw is designed according to the principle of combined block type. It has different functions of conventional and special screw elements. By reasonable design and combination, the screw can meet the needs of many complex technological processes, and the changes are almost infinite. Our company has rich experience and outstanding technical advantages in screw configuration development and design according to the ever-changing material and process requirements of different customers. The screw configuration of the machine is optimized for thePET flake material process;

* Screw element and core shaft are connected by involute spline;

* The screw elementmade from M2, after vacuum hardening, its hardnessis controlled whithin the range of HRC60~64;

* The screw element is made of special NC machine tool or CNC machining center, and the manufacturing precision level is leading in China.

5.2.4 AC main motor

* AC frequency conversion motor made in China;

* Power rating: 160kw;

* Rated speed: 1480r/min;

* Cooling-down method: Forced circulation cooling of self-contained fan;

* levels of protection: IP54;

* The technical performance conforms to the International Electrotechnical Commission IEC34-1 standard and the national standard GB755 requirements. The corresponding conditions for use are:

--Above sea level: ≤1000m;

--Ambient air temperature is not greater than 40℃;

--The working environment should not be acidic, alkaline or other gases that are corrosive to insulation;

--Motor is continuous working system(S1);

5.2.5 Torque distribution transmission box

* The latest improved version (patent design) of deceleration box, integral structure of deceleration and torque distribution, shafting and bearing selection have been optimized and promoted, the bearing capacity has been increased by more than 30% compared with the traditional configuration; the life of key radial bearings has been greatly extended to more than 20,000 hours;

* The key gear is made of top material and hard tooth surface design. Surface hardness HRC58-62, grinding accuracy 6 grade. Radial bearing adopts Japan NSK and other international famous brand product;

* The distribution box is made of CNC machining center, and the manufacturing precision is the leading in China;

* The design of gear oil-impregnated lubrication, coupled with forced circulation cooling system of lubricating oil, forced filtration and no oil cut improves the high operating reliability of the reducer. Pump motor power 0.55 kw, with heat exchanger;

* Import and output Shaft Oil Seal selected International famous Brand products;

* The input shaft coupling adopts laser alignment instrument to ensure high precision of assembly;

* Main technical parameters

--Input speed:1480r/min;

--Output speed:600r/min;

--Total reduction ratio:1:2.5.

5.2.6 Mainframe electric heating

* Except the firstbarrel for feeding and without any heating, all other barrelsare electrically heated with cast copper;

* Heating power:

--Closedbarrel copper-cast heater: 7.4kw/Section;

--Exhaustbarrel copper-cast heater: 4.8kw/Section;

--Die copper-cast heater: 3.2kw/Section;

--Total heating power of mainframe system: 64.6kw.

5.2.7 Soft water cooling system

The unit includes a water cooling pipeline system installed on the fuselage and a built-in circulating soft water tank; according to the need of temperature control of the cylinder, the cooling of the overheated cylinder is carried out by the automatic control of the circulating soft water. The external cooling water is cooled through the heat exchanger to realize the heat transfer balance of the circulating soft water.

* Water cooling piping systems include:

--Stainless steel inlet and outlet main pipe;

--Inlet and outlet water cooling branch pipes for eachbarrel;

--Manual flow regulating valve;

--Automatic control solenoid valve, adopting international famous brand products.

* The circulating soft water tank section includes:

--Stainless steel tank;

--Centrifugal water pump;

--The working temperature of TPE is relatively higher,a model of SL-418 condenser is used to improve the cooling effect;

--Fittings and valves;

--Filter and water temperature, water level indication;

* Technical parameter

Internal recycling water Boiler soft water (Deionized water)

The highest inlet temperature of inner circulationfor barrels 80℃

Thehighestbackwater temperature of inner circulation cylinder 130℃

External circulation water Ordinary cooling water

Outer circulation cooling water temperature ≤30℃

30 ℃ cooling water consumption ≤3m³/h

Pump motor power 0.55kw

Tank volume 140L

5.2.8 Vacuum pumping system:

The vacuum system is used to extract the invalid or harmful components such as water vapor, low molecular volatilization and so on, which are produced during the process of entrapment or processing in the separation material system, so as to ensure the performance of the product.

* The system includes:

--Water ring vacuum pump;

--Vacuum condenser (Vapor-liquid separation);

--Pipes, valves, vacuum meters, etc.;

--Exhaust chamber with window, flip structure;

* Vacuum pump technical parameters (Operating conditions:Water temperature 15℃, gas temperature 20 ℃, gas relative humidity 70%)

--Maximum pumping capacity52m³/hr

--Power of motor2.2kw

--Motor speed 1480rpm

--Supplementary water consumption~0.5m³/h

--Final vacuum ~0.088MPa

5.2.9 Screen changer & Die

* Granulation template: 19×¢3.0, Made from nitrideing steel

* Hydraulic non-stop double-station board type screen changer, made from nitrideing steel

* The maximum pressure of hydraulic station is up to 15Mpa

* Hydraulic pump displacement: 4ml/hr

* Motor power and speed: 1.5kw, 1400rpm

* Nitrogen charging pressure inside an accumulator: 7.3Mpa

* Weight of 40 kg

6. Cooling Water Channel:

* The length is6.0 meters and the material in contact with the strip is 304 stainless steel with a width of 800 mm. Whole movable, height adjustable;

* Water jet pump power 1.1 kW, cooling circulating water pump power 2, power 4kw;

* The water tank is provided with a cold water recharge pipe, a hot water return pipe.

7. Dryer:

* 50% The efficiency of blowing is increased by the structure of four out of air.;

* Fan power2.2kw. contact with material is stainless steel.

8. Gantry Pelletizer:

The granulator adopts double frequency conversion drive form, cutting tool speed and traction speed can be controlled separately. Particle fixed length selection PLC automatically matches the frequency of two frequency converters, and cuts out the selected length particles.

* Model LQ 600;

* Output: 600kg/hr,at 1g/cm3

* Number of entries: 17~21 strips

* Maximum 30 strips, with OD 3mm

* Strip speed: 20~90m /min

* Granulation moving & fixed knife: Using carbide blade

* Up feed roller: Wear-resistant & high-temperature rubber

* Down feed roller: S45C steel with hard chrome plating

* Drive motor: 7.5kw, IP 21, with frequency control

* Weight: About 600kg

* Compressed air should be supplied by 0.4~0.8Mpa(Consumption is very less)

9. Vibrating Screen:

|

Parameter |

|

1. Vibration motor 2 units 0.25kw. choose vibration motor of Sino-foreign joint venture |

|

2. Sieve screen, sieve seat use 304 stainless steel; Sieve seat thickness 5mm |

|

3. Transmission capacity:1.0 T/hr |

10. Finished Product Warehouse System

* Cooling conveying fan, motor power: 5.5kw

* Volume ofproduct warehouse: 1M3,made fromstainless steel

* One set of stainless steel air duct

11. Electronic Automatic Control System

* The whole control system includes temperature control system, drive system and interlock automatic control of unit;

* Temperature control range: 0℃~500℃;

* Japanese OMRON brand temperature controller to be used, the module of host system has the function of PID parameter self-tuning and so on;

* Bothmain motor and feed motor speed regulating device is Japanese Miyakawa Yurikiyasu“YOLICO” brand frequency conversion governor;

* The main low-voltage electrical components (Contactors, relays, circuit breakers, buttons, indicator lights, etc.) are all used Schneider and other international famous products;

* The structure of the electric instrument cabinet is a copy of Weitu structure, the space is spacious, the layout is reasonable, and it is easy to maintain;

* Interlocking and alarm:

--The interlocking protection between the twin-screw mainframe and the gearbox oil pump, that is, the main engine can only start after the oil pump is started;

--Main motor and auxiliary motor overcurrent, shutoff, lack of equal alarm protection shutdown.

Supplier: SHANGHAI OMEGA MACHINE CO., LTD

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-