Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

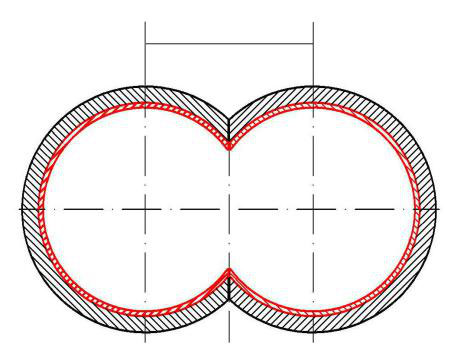

Universal Application Reason of Bimetallic C-type Liner

In China, the most popular segment barrel liner in twin-mixing field, the first and the undisputed、accounting for more than 80% of the market share is the bimetallic C liner made by Shanghai Omega Company, due to its exceptional service life and appropriate sales price. All kinds of inner liner, whether the bimetallic C-type liner or oval liner, were first developed by this company in China, based on its unremitting pursuit of quality, now well-known not only in mainland, but also in the global end-user market. Although there are currently dozens of manufacturers in china who can supply various types of liner, many end-users often request they twin extruders with Omega brand liners. As a direct result, now in Nanjing, China, more than 30 twin-screw extruder makers, including famous Nanjing Coperion, Nanjing KY, the vast majority of high-end extruders must be assembled with Omega brand liners. The root cause of the widespread application of Omega brand, not only because of its simple assembly and reasonable price, the more important reason is because of its special longer service life, which other companies who imitate the technology of Omega Company can not be compared.

As the research and development unit of bimetallic barrel and bimetallic screw 30 years ago, Shanghai Omega knows the key to the service life of the alloy protective layer on the liner surface, which is the material composition and its forming process. Therefore, in addition to strictly controlling the composition of the alloy material from the source, we had also applied for a national patent to strictly control the furnace molding process. Standard material composition of the source ensures that there are sufficient and suitable ingredients in the alloy material, which can guarantee a high proportion distribution of carbides in the alloy layer which play a key role in resisting wear (For more detailed in theory, please refer to our document [Keeping the ratio of hard phase inside alloy layer is first condition]). The unique patented molding equipment can keep the process in forming bimetallic liners, that these carbides can be formed rapidly under a suitable and a demanding temperature, which will not affect the uniform dispersion of the hard phase particles because of a low temperature, this will not lead to the stress concentration inside the metallographic structure of the metal material, will not lead to weaken the bonding strength between the alloy layer and the base metal. These demanding molding temperature conditions are essential to a bimetallic barrel or a bimetallic liner.

Some end users tell us that on the inner wall of some bimetallic C-type liners they received from other makers, slight cracks can often be fount, which expanded after a short period of use, the alloy layer was detached from the base metal, and the service life is greatly reduced. All the reason is the limitation of equipment and technical condition, there is no way to imitate the key molding process of the liner.

Shanghai Omega Machinery Co., Ltd ./ Chief Engineer's Office

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-