Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Where to get kinds of bimetallic barrels?

Feb 26,2018

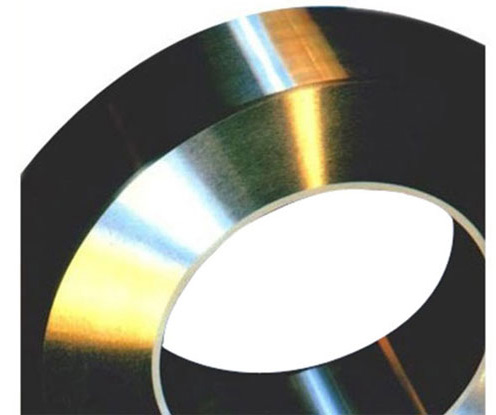

The features of bimetallic barrels are superior performance backing, inseparable insert bond, bimetallic bore inlay and bimetallic construction. The cast bimetallic barrels are well produced by metallurgically connecting the lining alloy to the interior surface of pre-machined, forging, bar stock or seamless steel tube. The bonding perfectly achieved through heating the barrel to the exact point and where the alloy point melted. The barrel is also cooled and spun along with centrifugally transmitting the alloy to the interior surface off the barrel.

We are the leading industry manufacturing bimetallic barrel with the experts. Besides, we offer the customer expected quality and right kind of barrels to meet their needs. We specifically focus on offering quality and competitive price that our linings range from corrosion resistant, premium and abrasion resistant providing diverse measures of wears resistance. We manufacture the huge collection of bimetallic barrels and fetches the manufacturing standard sizes of the barrel blanks to encounter the complete customer needs. Initially, we manufacture the excellent alloys utilized in producing the barrels and they created own material in the laboratory as well test continuously in the complicated operating conditions.

Prev News Next News

- Information

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-