Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

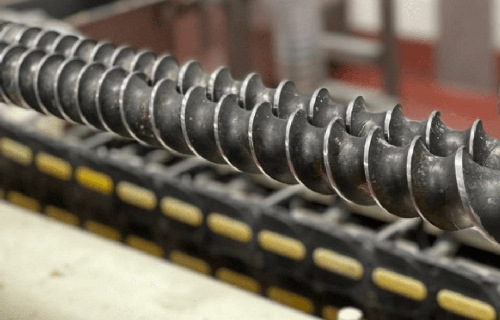

Which is better single screw or twin screw extrusion in food?

Nov 02,2023

Single-Screw Extrusion:

Simplicity: Single-screw extruders are generally simpler in design and easier to operate, making them suitable for a wide range of food products.

Cost: They are often more cost-effective than twin-screw extruders, both in terms of initial investment and maintenance.

Versatility: Single screw extruders can handle a variety of food products, including cereals, snacks, pasta, and pet food.

Low Shear: They provide relatively low shear forces, making them suitable for delicate or heat-sensitive ingredients.

Twin-Screw Extrusion:

Mixing and Homogenization: Twin screw extruders are excellent for thorough mixing, blending, and homogenization of ingredients. This is especially important for products like pet food, breakfast cereals, and functional foods.

Flexibility: They can be configured with various screw profiles and elements to achieve different processing objectives, such as cooking, texturizing, and shaping.

High Shear: Twin screw extruders can provide high shear forces, which can be beneficial for products requiring significant shearing, such as meat analogs and high-protein foods.

Ultimately, the choice between single-screw and twin-screw extrusion depends on the specific needs of your food product, production capacity, and budget. It's essential to consider the characteristics of the raw materials, the desired texture and properties of the final product, and the required production rate when making this decision. In some cases, a combination of both types of extrusion in a production line may be the most suitable approach to achieve the desired results. Consulting with food processing engineers and equipment suppliers is advisable to determine the best extrusion solution for your particular application.

Prev News Next News

- Information

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-