Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Ceramic Ultrafiltration Membrane Product And Its Production Process

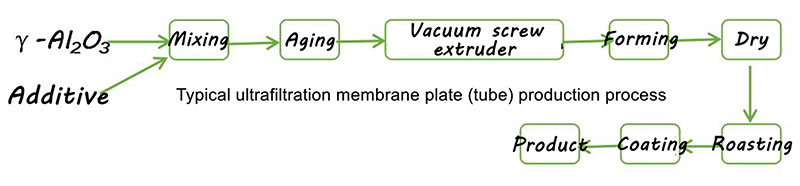

Ceramic ultrafiltration plate membrane can effectively remove organic matter, suspended matter, toxic and harmful substances (such as radium, arsenic), microorganism, algae and oil in liquid, and is the core and key component of new efficient separation technology. It is a kind of ultra-fine filter membrane with asymmetric structure, which is prepared by sintering process with inorganic materials such as alumina. Compared with the traditional organic membrane, it has the advantages of good chemical stability, good reliability, long service life, small occupation space, excellent pollution resistance and low energy consumption, which represents a development trend of water treatment membrane materials.

The service life of ceramic flat film is 3~5 times longer than that of polymer film, the membrane flux is 3~10 times higher, the consumption of chemical agent is reduced by 50 times, the cost of operation and maintenance and energy consumption are reduced by more than 50%. the contamination, chemical cleaning and oxidation of polymer ultrafiltration membranes are an inevitable conundrum, while ceramic membranes are easier to clean, more resistant to contamination, and there is no risk of oxidation.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-