Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Mask meltblown cloth equipment | Quickly Provide Mask Production Equipment

Now that the new coronavirus is sweeping the world, it is imperative to fully expand the production of masks. At present in China, the equipment for producing PP meltblown fabrics is in short supply. Due to benefited from intensive cultivation in the extrusion industry for nearly 30 years, with the support of many friends in the industry, we have expanded production capacity and now introduce the mask production eqipment to the market. All kinds of equipment for producing PP meltblown cloth with high stability and reliability, with high output and high cost performance, welcome to consultation.

The production of polypropylene PP medical-grade masks with excellent filtration capacity needs to go through the following three main production steps.

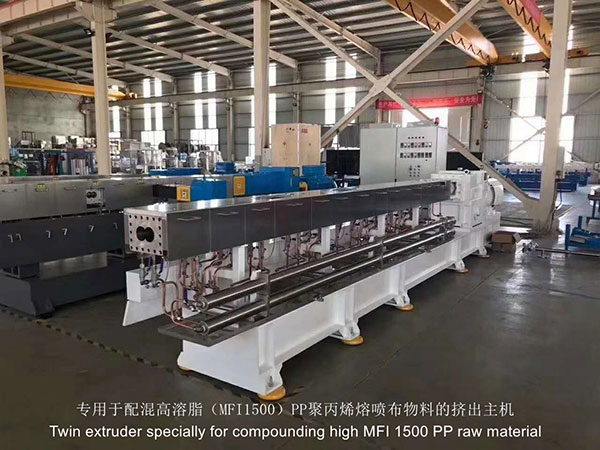

The first production step is to feed the polypropylene PP raw material, mixed with a certain proportion of free radical initiator (DCPD), lubricant (Erucyl amide) and antioxidant, into a feeding hole of a parallel twin screw extruder to be compounded, to get a ultra-high melt index MFI 1500 which is suitable for the raw material to make mask fabric by a melt-blown process way, referred to as the high melt index PP melt-blown material. Our company can provide users with detailed formula percentage of compounding PP melt-blown material, it is free.

Main Parameters of Twin Screw Extruder for PP Melt blown Production

|

PP Meltblown Cloth Width |

Daily Capacity |

Single Extruder Model |

|

600mm |

180kg |

SJ-45/33 |

|

800mm |

300kg |

SJ-55/33 |

|

1600mm |

1500kg |

SJ-90/33 |

|

2400mm |

2500kg |

SJ-105/33 |

|

3200mm |

4000kg |

SJ-135/33 |

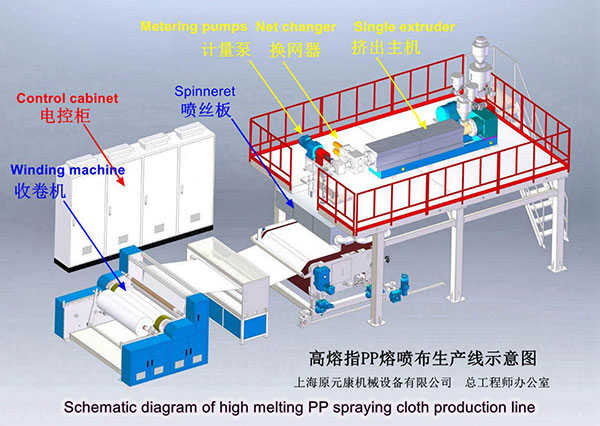

The second production step is to feed PP meltblown raw material, which or purchased, or self-made, mixed with a certain stabilizer, whitening agent and masterbatch, into a feeding hole of a single screw extruder. With a cooperation of auxiliary devices such as netting, metering pump, spinneret, and winder, PP melt-blown fabrics with different widths are manufactured.

The layout of the production process components is as follows:

According to the different widths of the meltblown fabric and the different output, our company can provide a multi-specification single-screw extruder with L/D30~33, and different auxiliary machines can be configured according to different requirements of users. The delivery period of PP melt blown fabric extruder of all specifications is within 40 days.

Single screw extruder parameters for PP meltblown cloth production

|

PP Meltblown Cloth Width |

Daily Capacity |

Single Extruder Model |

|

600mm |

180kg |

SJ-45/33 |

|

800mm |

300kg |

SJ-55/33 |

|

1600mm |

1500kg |

SJ-90/33 |

|

2400mm |

2500kg |

SJ-105/33 |

|

3200mm |

4000kg |

SJ-135/33 |

CHIEF ENGINEER OFFICE

SHANGHAI OMEGA MACHINERY CO., LTD- Information

- During the production of cross-linked polyethylene cables, early cross-linking often occurs. What causes this phenomenon and how can it be solved?

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-