Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

The Unsung Hero: Understanding the Critical Role of the Screw Element

Jul 14,2025

Have you ever stopped to consider the intricate components that make modern manufacturing possible? Often, the most crucial parts are the ones we rarely see, working tirelessly behind the scenes. In the world of plastics, rubber, and food processing, one such unsung hero is the screw element. These meticulously engineered components are at the very heart of extrusion and injection molding machines, dictating everything from material quality to production efficiency. At OMEGA, we specialize in crafting high-performance screw elements that are the backbone of your production line.

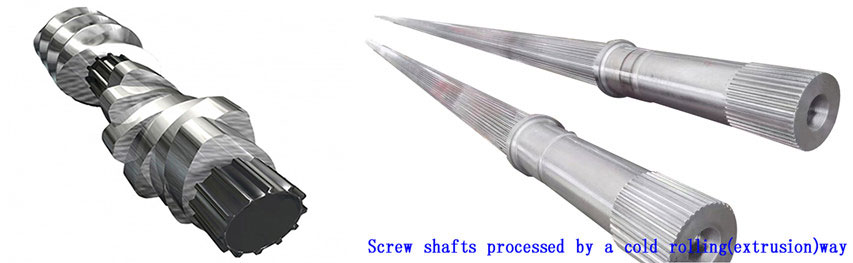

A screw element is a modular segment that, when assembled, forms the complete screw of an extruder or injection molding machine. Each segment is designed with specific geometries – such as conveying, mixing, or kneading sections – to perform a particular function in the processing of materials. These elements work in harmony within the barrel, melting, blending, and conveying raw materials under precise temperature and pressure conditions, ultimately shaping the final product. Their design is critical, as it directly impacts melt quality, output, and energy consumption.

The Engineering Behind a High-Performance Screw Element

The effectiveness of any extrusion or injection molding process hinges significantly on the design and quality of its screw element. It’s not just about moving material; it's about achieving homogeneous melt, optimal dispersion of additives, and efficient heat transfer. This requires deep engineering expertise, precise manufacturing, and an understanding of material science. Different polymers and applications demand different screw geometries, from single-flight designs to complex kneading blocks and mixing sections.For example, in a bustling plastic recycling facility in China, the ability to process various types of reclaimed plastics efficiently relies heavily on robust and adaptable screw elements. A poorly designed or worn element can lead to inconsistent melt, degraded product quality, and frequent downtime. This highlights why investing in expertly crafted screw elements, designed for durability and optimal performance, is not just an expense, but a strategic decision for any manufacturer aiming for excellence.

Key Advantages of Quality Screw Elements

Choosing the right screw elements from a reputable manufacturer can dramatically enhance your operational efficiency and product quality.-Improved Melt Homogeneity: Ensures consistent blending and melting of raw materials, leading to higher quality end products.

-Enhanced Dispersion: Efficiently mixes additives, colorants, and fillers throughout the polymer matrix.

-Increased Output & Efficiency: Optimized designs can lead to higher throughput and reduced energy consumption.

-Extended Lifespan: Manufactured from wear-resistant materials to withstand abrasive and corrosive environments, reducing maintenance.

-Customization: Elements can be designed and configured to suit specific materials and processing requirements.

-Reduced Downtime: Reliable performance minimizes unexpected breakdowns and costly production interruptions.

At OMEGA, we pride ourselves on our meticulous approach to designing and manufacturing screw elements. Our expertise spans a wide range of applications, and we utilize advanced materials and precision machining to deliver components that ensure your machines operate at their peak performance. We understand that every degree and every rotation matters in achieving superior product outcomes.

FAQs About Screw Elements

Q1: What materials are screw elements typically made from? A1: Screw elements are commonly made from high-quality alloy steels like nitrided steel, tool steel (e.g., D2, H13), and various stainless steels, often with special surface treatments for wear and corrosion resistance.Q2: How often should screw elements be inspected or replaced? A2: Inspection frequency depends on the processed material (abrasiveness, corrosiveness), operating conditions, and hours of use. Regular checks for wear are crucial for maintaining efficiency.

Q3: Can screw elements be repaired? A3: Some wear can be addressed through re-welding and machining, but extensive wear often necessitates replacement to maintain optimal processing characteristics.

Q4: Do different materials require different screw element designs? A4: Absolutely. The viscosity, melting temperature, and shear sensitivity of different polymers and materials (plastics, rubber, food) require specific screw geometries for optimal processing.

Q5: What are the signs of a worn screw element? A5: Signs include reduced output, increased melt temperature variations, poor mixing, higher energy consumption, and inconsistent product quality.

Powering Your Production with Precision

The humble screw element is far from insignificant; it's a powerhouse component that determines the success of your extrusion and injection molding processes. By choosing high-quality, precisely engineered screw elements, you are investing in the efficiency, reliability, and profitability of your production line. At OMEGA, we are committed to providing the superior components that empower industries in China and around the world to achieve unparalleled manufacturing excellence. Let us help you optimize your process from the inside out.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-