Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

The Unsung Hero: Why a Quality Screw Element is Critical for Extrusion Success

Jun 17,2025

Have you ever considered the intricate components that make modern manufacturing possible? Often, the most crucial parts are the ones we rarely see. In the world of plastics and rubber processing, the screw element is precisely such a hero. It's the beating heart of an extruder, directly impacting product quality, production efficiency, and overall operational costs. At OMEGA, we understand this profound importance, dedicating ourselves to manufacturing high-precision screw elements that drive industry forward.

Understanding the Core: What is a Screw Element?

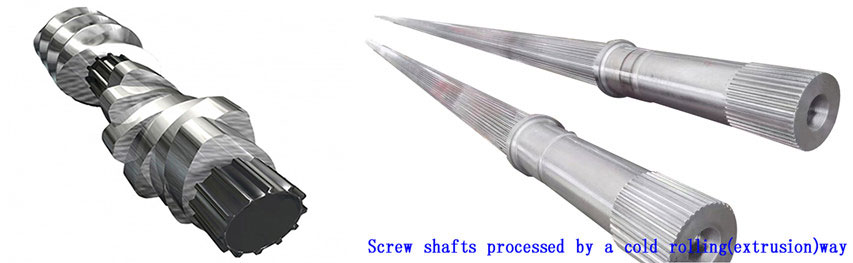

A screw element is a specialized component forming part of an extruder screw, typically found in twin-screw extruders. These elements are arranged in various configurations along a shaft, working in unison to convey, melt, mix, and homogenize raw materials like plastics, rubber, and food products. Their precise design and high-quality construction are vital for achieving optimal material processing, ensuring consistent product quality, and maximizing throughput. The right screw element ensures efficient material flow and prevents issues like degradation or uneven mixing.

OMEGA: Precision Engineering for Optimal Performance

As a leading manufacturer, OMEGABARRELSCREW prides itself on delivering meticulously engineered screw elements that meet the highest industry standards. We utilize advanced materials and precision manufacturing techniques to produce elements renowned for their wear resistance, corrosion resistance, and exceptional durability. Our extensive range includes various designs and configurations, from conveying and kneading blocks to mixing elements, tailored to suit diverse processing needs. We understand that every application is unique, and our expertise allows us to provide customized solutions that optimize your extrusion process.

The Impact of a Superior Screw Element

The quality of your screw element directly influences several critical aspects of your production:-Product Quality: High-precision elements ensure thorough mixing and consistent melting, leading to uniform and high-quality end products.

-Production Efficiency: Optimized designs reduce energy consumption and increase throughput, boosting overall productivity.

-Reduced Downtime: Durable and wear-resistant elements minimize breakdowns and maintenance, extending the lifespan of your extruder.

-Cost Savings: By improving efficiency and reducing maintenance, a high-quality screw element translates to significant long-term cost savings.

OMEGA: Your Partner in Extrusion Excellence

Our commitment at OMEGA goes beyond just manufacturing. We work closely with our clients to understand their specific processing challenges and recommend the most suitable screw element configurations. Our team of experienced engineers provides technical support and expertise, ensuring that you achieve optimal performance from your extrusion lines. We are dedicated to providing solutions that enhance your profitability and maintain your competitive edge in the market. We are a trusted name in China and globally for high-quality extruder components.

FAQs About Screw Elements

Q1: How do I choose the right screw element for my extruder?oA1: Choosing the right screw element depends on the material being processed, desired output, and specific application. Consulting with experts like OMEGABARRELSCREW can help in selecting the ideal configuration.

Q2: What materials are screw elements typically made from?

oA2: Screw elements are commonly made from high-grade tool steels (e.g., D2, H13) or specialized alloys (e.g., nickel-based alloys) to ensure wear and corrosion resistance, depending on the processing conditions.

Q3: How often should screw elements be replaced?

oA3: The lifespan of screw elements varies based on material abrasiveness, processing temperatures, and operating hours. Regular inspections and maintenance can help determine optimal replacement intervals.

Q4: Can worn screw elements affect product quality?

oA4: Yes, worn screw elements can lead to inconsistent mixing, uneven melting, reduced throughput, and ultimately, a decline in final product quality.

Q5: What is the role of screw element geometry?

oA5: The geometry (pitch, flight depth, number of starts) of a screw element is crucial as it dictates material conveying, compression, melting, and mixing efficiency, directly impacting extruder performance.

Optimize Your Extrusion with OMEGA!

Don't let subpar components hinder your production. Invest in the quality and precision of a OMEGA screw element. Contact us today to discover how our expertly crafted components can elevate your extrusion processes and contribute to your long-term success.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-