Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

What is a screw barrel?

Dec 18,2023

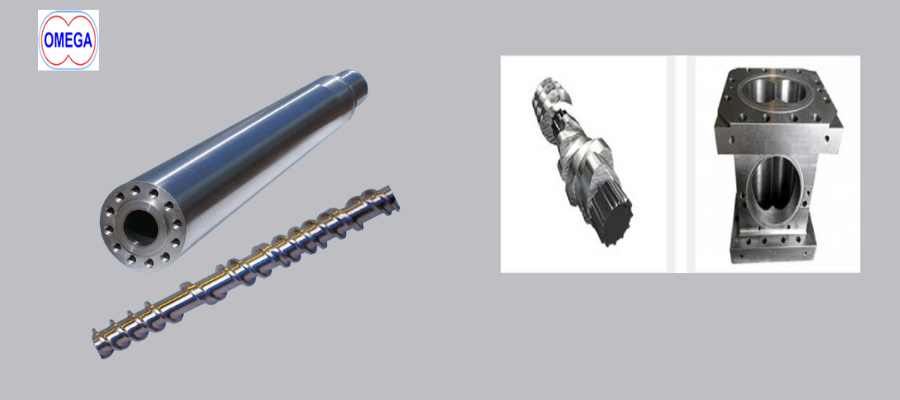

A screw barrel, additionally called a Barrel and screw meeting, is a crucial issue within the extrusion screw and injection molding screws strategies used within the plastics industry. It consists of a feed screw and a barrel that work collectively to soften, mix, and delivery plastic material through a molding machine.

Screw Barrel: Essential Component in Plastic Processing Machines

Screw: The screw is a helical rod that rotates within the barrel. Its primary function is to push, pull, and compress the plastic material because it actions alongside the barrel. The layout of the screw, including its screw flights intensity, pitch, and compression ratio, plays a essential role within the plastic processing system.

Barrel: The barrel is a cylindrical chamber thru which the screw passes. It presents the vital conditions for heating, melting, and combining the plastic cloth. Barrels are regularly equipped with heating elements to control temperature, and they will have extraordinary zones with varying temperatures to optimize the injecting molding method.

Understanding the Screw and Barrel Functions

- Screw: responsible for pushing and mixing the materials

- Barrel: Provides operating area and aid for the screw

- Transmission gadget: responsible for transmitting energy to the screw

The plastic fabric, typically in the shape of pellets or granules, is fed into the barrel, where it's miles progressively heated and compressed by using the rotating feed screw. As the material moves along the extruder screws barrels, it undergoes a melting and combining method, becoming a homogeneous molten mass. The molten plastic is then compelled through a die to provide it the favored form.

Key Takeaways Barrel and Screw

- The market length of screw barrels is predicted to attain US$10 billion

- Understanding the connection between barrel and screw is crucial for screw barrel optimization

- Screw barrels are extensively used in plastic processing, rubber product manufacturing, and meals processing

- The center characteristic of screw element is to enhance the performance and great of the screw barrel

- Technical traits and overall performance parameters are key elements in deciding on the proper screw barrel

Characteristics and Performance Parameters of the Barrel and Screw

|

Technical Parameters |

Describe |

|

Material |

Screw barrels made of different substances have one of a kind put on and corrosion resistance |

|

Size |

The length of the screw barrel immediately impacts manufacturing ability and performance |

|

Pressure |

The screw barrel strain parameters decide the maximum strain bearing capability |

The design of the sorts of screw barrel assembly can vary depending at the specific necessities of the plastic cloth being processed and the sort of molding method being used. Different materials and methods may also necessitate versions in flat head screw geometry, duration, and fabric, as well as floor remedy, barrel construction, and heating methods.

Final Words

Overall, the performance of the screw barrel meeting is vital for accomplishing steady and high satisfactory plastic merchandise within the molding enterprise. In a few cases, while the screw may be rebuilt, it allows in decreasing charges. Companies additionally offer restore and rebuild solutions, which include barrel repair, repair services, and upkeep for twin screws. These services make sure fee effective production even as maintaining a dependable lead time. Additionally, additives such as barrel nuts play a function in securing the assembly for smooth operation.

Prev News Next News

- Information

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Why does the cooling process for profile extrusion become unbalanced?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-