Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Bimetallic Barrel & Bimetallic Screw in China

Mar 25,2016

1.Research Background of Bimetallic Barrel & Bimetallic Screw

As a very important replace materials, plastic and rubber are used more and more. Therefore, various modified plastic---rubber are used widespread. For instance, some calcium, carbonate, kadine are added in the plastic---rubber for modifing, some fibrous glass、carbon fibre、boron fibre are added in plastic---rubber for enhancement. Due to putting these filler and reinforcer, the plastic's characteristics are changed. That shall make the plastic---rubber suitable for special purpose. But on the other hand, it can make the machinery heart - Barrels and screws to be seriously corroded and worn. These things will cost much time and manpower to repair or replace these parts. The production will go down.

The chief leading member of our Shanghai Omega Group Is the first creator in the bimetallic technology In the last century 80 's in China, researched and developed different kinds of alloy protective coat for the bimetallic barrel and bimetallic screw. After years of constantly to exploration and improved, the bimetallic barrel and bimetallic screw protected by different kinds of wear-resistant and corrosion-resistant alloy, to its excellent operation life and unmatched cost-performance, by industry widely praised, has made a significant contribution to the development of the country's industry.

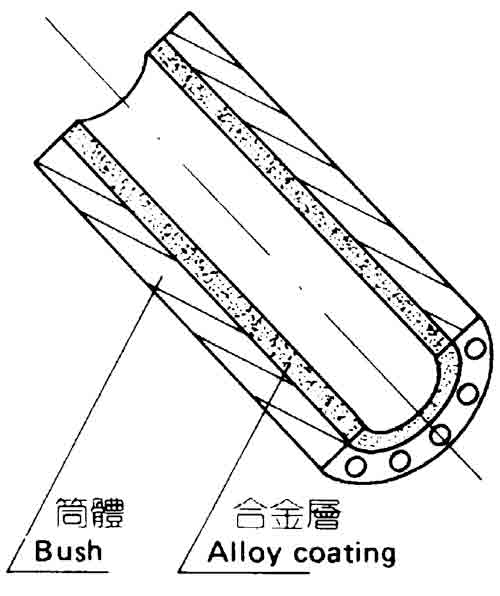

2.What is the Bimetallic Barrel? How Many Kinds of Armour Alloy Layer There Are for The Bimetallic Barrel?

The Bimetallic barrel consists of a general base material and an armoured layer which is homogeneously attached to the base material on inner diameter surface. It has an certain thickness and certain hardness. This layer is a wear-resistant alloy, or corrosion-resistant alloy, or both functions. This armouring layer is locked on base material in metallographic structure. These two kinds of material take different functions in hand, but form an uniform whole - The bimetallic barrel.

Three kinds of armouring layer and its data of bimetallic barrel:

|

Properties |

Ω101 Alloy |

Ω201 Alloy |

Ω301 Alloy |

|

|

Wear Resistance |

★★★ |

★★ |

★★★ |

|

|

Corrosion Resistance |

★ |

★★★ |

★★★ |

|

|

Main elements |

Fe-Ni-B |

Ni-Co-Cr-B |

Fe-Cr-Ni-B-Carbide |

|

|

Hardness(HRC) |

58~64 |

50~56 |

55~65 |

|

|

Breaking strain(%) |

0.30 |

0.24 |

0.20 |

|

|

Elastic strain ( kgf / mm ) |

18600 |

215000 |

22000 |

|

|

Coefficient of thermal expansion (/℃) |

15℃~250℃ |

10.0×10-6 |

11.9×10-6 |

11.2×10-6 |

|

15℃~400℃ |

10.5×10-6 |

12.6×10-6 |

11.9×10-6 |

|

““★”Marks:★★★ Excellent ; ★★ Very good; ★ Good

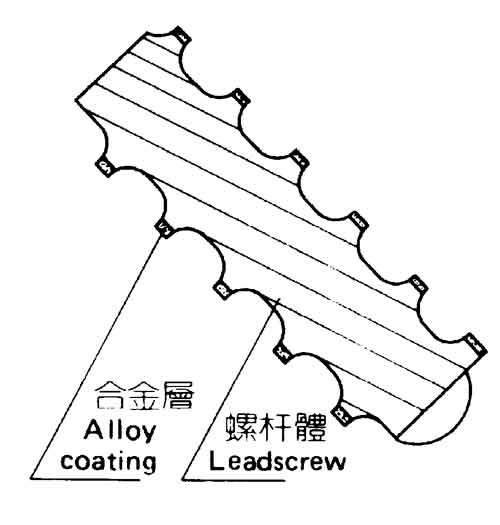

3.What is the Bimetallic Screw? How Many Kinds of Armour Alloy Layer There Are for The Bimetallic Screw?

There is an armouring layer on the top of screw thread, or on the surface of all over the screw working surface. It has a minimum contact wear ratio then it is running on the inside of barrle. The base material is one kind of high-strength and weldable、nitridable metal. Between this armouring layer and the base material, there is perfect material bonding. These two kinds of material take different functions in hand, but form an uniform whole - The bimetallic screw.

Three kinds of armouring layer and its data of bimetallic screw::

|

Alloy Name |

Hardness(HRC) |

Properties |

|

|

Wear Resistance |

Corrosion Resistance |

||

|

FX 1 |

38~42 |

★ |

★★★★ |

|

FX 2 |

45~50 |

★★ |

★★★★ |

|

FX 3 |

52~56 |

★★★ |

★★★★ |

|

FX 4 |

58~60 |

★★★★ |

★★★★ |

|

Layer Thickness: 1.0~2.0mm |

|||

““★”Marks:★★★ Excellent ; ★★ Very good; ★ Good

Base Material of Bimetallic Barrel & Bimetallic Screw

|

Base Material |

Hardness |

Tensile Strength |

Applications |

|

S 45 C(45#) |

HS 24~28 |

40~50 kg f / mm2 |

Extruder |

|

SCM 440(40Cr) |

HS 28~40 |

65~80 kg f / mm2 |

Extruder & Injection |

|

SACM645 ( 38CrMoAlA ) |

HS 30~43 |

70~80 kg f / mm2 |

Extruder & Injection |

|

SNCM 439 ( G10CrNi3Mo ) |

HS 35~45 |

70~85 kg f / mm2 |

High-pressure Injection |

|

SUS 316 ( 0Cr17Ni12Mo2 ) |

HS 18~28 |

45~60 kg f / mm2 |

Corrosion-resistant Part |

Chief Engineer Office / Shanghai Omega Machinery Co., Ltd

Prev News Next News

- Information

- During the production of cross-linked polyethylene cables, early cross-linking often occurs. What causes this phenomenon and how can it be solved?

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-