Copyright © Shanghai Omega Machinery Co., Ltd. All rights reserved.

Top Materials Used in Barrel and Screw Manufacturing

Nov 07,2025

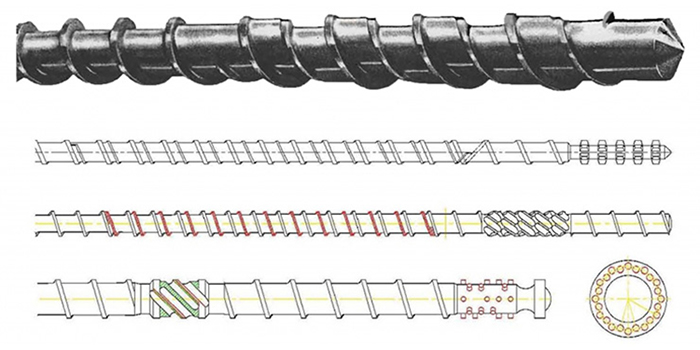

Within the global of plastic extrusion and injection molding, the barrel and screw meeting is the backbone of the procedure. These additives decide now not simplest the machine’s performance but additionally the pleasant and consistency of the very last product. Selecting the right fabric for a barrel and screw is therefore critical—it influences wear resistance, temperature endurance, and normal lifespan. This guide explores the top substances utilized in barrel and screw manufacturing, their blessings, and the way they effect business performance.

1. Knowledge the position of Barrel and Screw materials

A barrel and screw assembly is uncovered to severe warmness, friction, and corrosive polymer compounds throughout operation. As a end result, materials must provide sturdiness, electricity, and resistance to each abrasion and corrosion. The wrong fabric desire can result in premature wear, decreased throughput, and costly downtime.Modern-day producers cautiously fit materials to unique processing desires—whether or not handling glass-filled resins, %, or high-temperature engineering plastics. Let’s discover the most usually used materials in today’s manufacturing panorama.

2. Nitrided steel: The enterprise standard

Nitrided metal (generally 38CrMoAlA or 41CrAlMo7) remains the most extensively used cloth for barrel and screw manufacturing. The nitriding technique hardens the outer layer through nitrogen diffusion, developing a hard, put on-resistant floor at the same time as retaining a ductile middle.Advantages:

●Notable put on and fatigue resistance

●Correct for widespread-purpose packages

●Fee-effective answer for non-reinforced polymers

But, nitrided metal can war with fairly filled or corrosive substances, making it less perfect for specialised operations.

3. Bimetallic Alloy Barrels: enhanced sturdiness

When excessive put on or corrosion resistance is needed, bimetallic barrels are the cross-to choice. These are metal barrels lined with an alloy layer together with nickel-boron or tungsten carbide, which offers awesome protection.Advantages:

●2–five instances longer lifespan than nitrided barrels

●Advanced resistance to abrasive fillers like glass fiber or calcium carbonate

●Stable performance at higher processing temperatures

At the same time as the excellent barrel and screw setups often feature bimetallic barrels, they also come at a higher fee. But, the funding can pay off with reduced protection and downtime.

4. Stainless steel: perfect for Corrosive Polymers

For processing halogenated or flame-retardant polymers that release corrosive gases, chrome steel substances which include SUS440C or 17-4PH are desired. Those alloys withstand rust and chemical assault even as retaining mechanical integrity under excessive pressure.Applications:

●P.C extrusion and injection

●Chlorinated and fluorinated polymer processing

●Meals-grade or medical-grade plastics manufacturing

Stainless-steel screws and barrels can be greater high priced prematurely, but they ensure reliable long-term overall performance in harsh environments.

5. Device Steels and Hardened Alloys: For extreme conditions

Advanced device steels like D2, H13, and CPM alloys offer the last aggregate of hardness and longevity. These substances are engineered for environments wherein polymers incorporate abrasive components inclusive of glass fibers, titanium dioxide, or mineral fillers.Key capabilities:

●First-rate resistance to abrasive put on

●Keeps energy at excessive running temperatures

●Normally used for each screws and barrel liners

While paired efficaciously, a hardened alloy barrel and screw can outperform fashionable setups through years, particularly in heavy-responsibility extrusion or recycling traces.

6. Rising substances and Coatings

Recent advancements have delivered thermal spray coatings and carbide composites that further decorate overall performance. Those coatings are applied to screw flights and barrel interiors, minimizing friction and increasing lifespan regardless of difficult materials.Examples include:

●Tungsten carbide thermal spray coatings

●Nickel-boron diffusion coatings

●Ceramic composite linings

Such innovations allow manufacturers to preserve excessive output prices while minimizing renovation, energy use, and alternative expenses.

7. Deciding on the right material combination

Choosing the best barrel and screw fabric depends on three major factors:1.Polymer type – Abrasive or corrosive resins need high-resistance alloys.

2.Processing temperature – excessive-heat packages require strong tool steels or bimetallic designs.

3.Budget and lifespan desires – A cheap barrel and screw would possibly work for short-time period runs, however for continuous operation, making an investment in durable alloys ensures long-time period financial savings.

Consulting a dependable manufacturer like omegabarrelscrew can help you stability fee, performance, and longevity on your precise utility.

FAQs approximately Barrel and Screw materials

1. What is the most not unusual material for barrel and screw production?

Nitrided steel is the maximum commonplace because of its balance of price, power, and put on resistance for fashionable plastic processing operations.2. What is the distinction between nitrided and bimetallic barrels?

Nitrided barrels are floor-hardened, while bimetallic barrels have an internal alloy lining, presenting superior resistance to wear and corrosion.3. Are stainless steel barrels appropriate for all plastics?

Now not necessarily. Chrome steel is pleasant for corrosive or food-grade substances but won't be perfect for distinctly abrasive applications.4. When must I replace my barrel and screw?

Alternative is usually recommended whilst output consistency drops, melt stress fluctuates, or screw put on reaches 0.Five mm or extra intensive.5. Are reasonably-priced barrel and screw assemblies dependable?

They could paintings for light-responsibility or short-time period operations, but for non-stop or excessive-load production, investing in first-class substances is more fee-powerful.

Very last thoughts

The materials utilized in barrel and screw production directly influence efficiency, output fine, and long-time period working expenses. Whether or not you pick nitrided metal, bimetallic alloys, or superior tool steels, know-how your polymer type and production desires will assist you are making the best preference. For long-lasting overall performance and tailored answers, partnering with depended on producers is fundamental to achieving steady, terrific outcomes.

- Information

- What are the reasons for the bending and deformation of extruded plates? How can they be solved?

- What are the causes and solutions for uneven edges when extruding sheet materials?

- How to solve the problem of stripes appearing on the surface when producing ABS composite boards?

- What causes the appearance of pits and bubbles on the surface of ABS/PMMA co-extruded composite sheets? How can it be solved?

- Why does overflow occur at the exhaust port of the extrusion main machine when producing ABS multi-layer composite plates? How should it be handled?

- What are the differences in the process when producing UPVC pipes by directly extruding PVC granules and powder?

- How should one select the molding equipment when generating PP water supply pipes?

- Why do the surfaces of extruded profiles have weld marks when extruding? What are the solutions to eliminate these marks?

- Why do large, dull and unreflective bubbles appear on the surface of the special profiles? How can this problem be solved?

- What causes the uneven surface and poor gloss of the sheet during the sheet extrusion process? How can it be solved?

- Contact Us

-

Shanghai Omega Machinery Co., Ltd.

Add.: No.168 Hualian Road, Putuo District, Shanghai City

Contact: Nina

Tel.: +86-021-69921527

Mobile: +86-15021464410

Fax: +86-021-69921567

E-mail: omegajessica@163.com;965425705@qq.com

WeChat No.: 1131449532

Whatsapp: +86 159 0054 6558

-